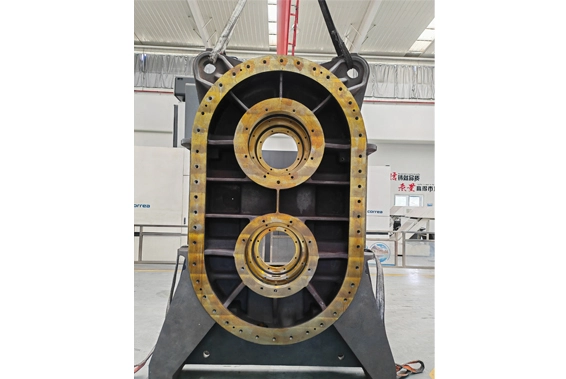

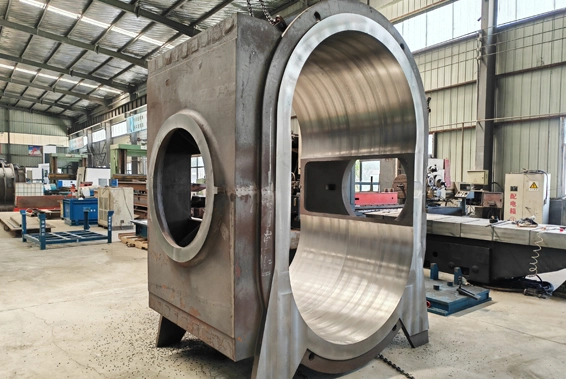

Our Roots Blower castings with finish machining are ideal for industries such as wastewater treatment, pneumatic conveying, chemical processing, and other applications where high-performance air displacement is required. Whether you are looking for custom solutions or standard parts, we guarantee exceptional quality and performance that meet or exceed your expectations.

With a focus on innovation, precision, and reliability, WALKSON is your trusted partner for premium Roots Blower components that deliver consistent, long-lasting results.

Roots Blower systems, renowned for their reliability and efficiency in air and gas handling, are used across a variety of industries where consistent airflow and pressure are critical. The high-quality castings with finish machining play a key role in ensuring the superior performance of Roots Blowers, making them indispensable in several demanding applications. Here are some of the key industries and applications where Roots Blower castings with finish machining are utilized:

1. Wastewater Treatment

· Application: Roots Blowers are commonly used in aeration systems within wastewater treatment plants, where they provide consistent air flow to aerate sewage or wastewater.

· Role of Castings: The castings form critical parts like blower housings, impellers, and rotors that need to withstand harsh environments, corrosive substances, and high pressures. The precision finish machining ensures smooth operation, preventing friction, wear, and inefficiency.

2. Pneumatic Conveying Systems

· Application: In industries such as food processing, pharmaceuticals, plastics, and chemicals, Roots Blowers are used to move bulk materials via pneumatic conveying.

· Role of Castings: The castings form the body and rotor components of the blower that must operate efficiently to provide the necessary air flow for transporting powders, granules, and other materials. The high-quality castings and finish machining ensure minimal leakage, long-term performance, and precise air volume control.

3. Chemical and Petrochemical Industries

· Application: Roots Blowers are used in chemical reactors, gas booster stations, and combustion air supply in petrochemical plants. They help supply or exhaust gases at consistent pressures for various processes.

· Role of Castings: The blower components, especially the housings and rotors, must be made from high-strength, corrosion-resistant materials. The finish machining ensures the critical sealing surfaces and rotational parts are accurate and wear-resistant, ensuring efficient operation under high-temperature, high-pressure environments.

4. Air Supply for Combustion

· Application: Roots Blowers are used to supply air for combustion in furnaces, boilers, and incinerators, where precise control of air flow is essential to optimize fuel efficiency and reduce emissions.

· Role of Castings: The castings form the blower body, rotors, and housing components which are required to be airtight and durable, even under extreme conditions. Finish machining of the rotor shafts and internal components ensures smooth operation, reduces power consumption, and ensures the blower maintains optimal pressure ratios.

5. Vacuum Systems

· Application: Roots Blowers are used in vacuum systems, such as in drying processes, packaging, and printing applications, where consistent suction is required.

· Role of Castings: The blower’s components, such as impellers and pressure relief valves, are made from precision castings to ensure high vacuum levels are maintained. The finish machining ensures minimal leakage, optimal pressure, and noise reduction, contributing to the overall efficiency of the system.

6. Mining and Quarrying

· Application: In mining operations, Roots Blowers are used for ventilation and dust control, supplying the necessary airflow to ensure a safe working environment.

· Role of Castings: The castings form heavy-duty components like blower rotors and casing parts, which need to withstand the abrasive environment and frequent operational stress. Finish machining ensures that parts are durable, with minimal maintenance requirements, even in harsh conditions.

7. Environmental Control Systems

· Application: Roots Blowers are often utilized in air filtration and odor control systems, where they help supply air to scrubbers or filtration units that remove contaminants from air or water.

· Role of Castings: The blower components need to be corrosion-resistant and able to handle a variety of gases and chemicals. The precision machining process ensures that components such as sealing surfaces and impellers are designed for tight tolerances to maintain high efficiency and low maintenance requirements.

8. Industrial Drying Processes

· Application: Roots Blowers are used in drying chambers for applications such as textiles, paper, and food products, where a consistent and high-volume air flow is needed to reduce moisture.

· Role of Castings: The blower housings and rotors are produced from high-quality castings to withstand the pressure and wear associated with industrial drying systems. The finish machining ensures uniform airflow and proper rotor function, which is crucial for consistent drying performance.

9. HVAC Systems

· Application: Roots Blowers can be used in large-scale heating, ventilation, and air conditioning (HVAC) systems to provide the required airflow and pressure for air handling units, especially in large commercial or industrial buildings.

· Role of Castings: The blower’s rotors and housings must be made from durable materials that can handle constant, high-pressure airflow. The finish machining ensures precise dimensions and proper sealing, which improves overall system performance and energy efficiency.

10. Aquaculture and Fish Farming

· Application: Roots Blowers are used in aeration systems for aquaculture, such as in fish farming or shrimp farming, where oxygen levels need to be controlled to maintain the health of aquatic life.

· Role of Castings: The castings of rotors and casing parts must be resistant to corrosion and designed to operate in continuous, harsh underwater conditions. Precision finish machining ensures that the air flow is consistent and energy-efficient, providing optimal conditions for aquatic life.

Key Benefits of Roots Blower Castings with Finish Machining:

· Enhanced Durability: The use of high-quality castings ensures that the Roots Blower components can withstand high-pressure, high-temperature, and corrosive environments.

· Improved Efficiency: Finish machining guarantees precise tolerances, smooth surfaces, and proper clearances, reducing friction and energy loss during operation.

· Long-Term Reliability: Precision machining ensures the longevity of Roots Blower components by minimizing wear, reducing the need for frequent maintenance, and extending operational life.

· Cost-Effectiveness: High-quality, finished components reduce the need for further processing and provide seamless integration into complex blower systems, saving time and money.

Conclusion

Roots Blower castings with finish machining offer significant advantages across a wide range of industries. By ensuring precision and durability, these components optimize the performance and longevity of Roots Blower systems. Whether used in wastewater treatment, pneumatic conveying, combustion air supply, or other critical applications, our high-quality castings and machined parts deliver outstanding efficiency and reliability, making them the ideal choice for industrial air-handling solutions.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi