Normalizing Heat Treatment for Castings and Forgings

Introduction:

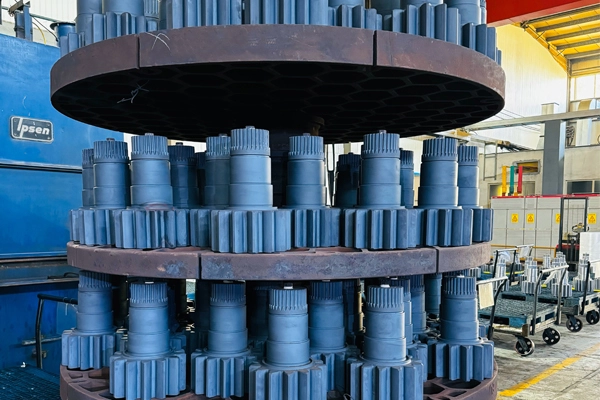

Normalizing is a vital heat treatment process designed to refine the grain structure of castings and forgings, ensuring consistent mechanical properties and improving overall material performance. This process is particularly beneficial for steel-based materials, enhancing their strength, toughness, and ductility, making them more suitable for demanding applications. Normalizing involves heating the material to a specific temperature above its critical point, followed by controlled air cooling, which results in a uniform and refined microstructure.

Objective of Normalizing for Castings and Forgings

Normalizing is performed with the aim of achieving the following key benefits:

Uniform Microstructure: To create a more uniform microstructure that enhances the mechanical properties across the entire component, eliminating segregation and improving consistency.

Enhanced Strength and Toughness: To increase both the strength and toughness of the material, improving its ability to withstand mechanical stress and fatigue during service.

Improved Ductility and Workability: To reduce brittleness and improve the material's ability to be further processed, such as machining, welding, or forming.

Refined Grain Structure: To reduce the grain size of the material, leading to improved mechanical properties such as tensile strength, hardness, and impact resistance.

Dimensional Stability: To reduce the internal stresses that may have been induced during the casting or forging process, thereby enhancing the stability and precision of the component during further processing.

Normalizing Process for Castings and Forgings

1. Heating:

The casting or forging is heated to a temperature above its critical range, typically between 800°C to 950°C (1,470°F to 1,740°F) depending on the alloy and specific material requirements. This temperature is carefully controlled to ensure that the material is uniformly heated throughout its volume.

2. Soaking:

Once the target temperature is reached, the material is held (soaked) at this elevated temperature for a specific duration, allowing the internal structure to become homogeneous. The soaking time ensures that the temperature is evenly distributed across the entire component.

3. Air Cooling:

After soaking, the material is removed from the furnace and allowed to cool in ambient air. Unlike quenching, which involves rapid cooling, normalizing involves slower, air cooling, which prevents distortion while still refining the material’s microstructure. The cooling rate is controlled to ensure that the material retains its uniform properties and dimensional stability.

Benefits of Normalizing for Castings and Forgings

1. Improved Mechanical Properties:

Normalizing results in a finer, more uniform grain structure, which leads to improved mechanical properties such as tensile strength, impact toughness, and fatigue resistance. These enhancements make the material more suitable for high-performance applications in which reliability and durability are critical.

2. Enhanced Ductility and Toughness:

3. Stress Relief:

During casting or forging, internal stresses can be created within the material due to rapid cooling or uneven heat distribution. Normalizing relieves these stresses by promoting a more uniform structure, reducing the risk of distortion or cracking during further processing or in-service operation.

4. Consistent Material Properties:

5. Improved Machinability:

Materials that undergo normalizing are often easier to machine, weld, or further process due to the refinement of their grain structure. This reduces tool wear, improves surface finishes, and helps achieve tighter tolerances during subsequent operations.

6. Enhanced Dimensional Stability:

Types of Materials Suitable for Normalizing

Normalizing is most commonly applied to carbon steels and alloy steels, but it can also be used for other ferrous and non-ferrous alloys. Materials commonly treated with normalizing include:

Carbon Steels: For structural applications, automotive components, and machinery parts requiring increased strength and toughness.

Alloy Steels: For parts that need enhanced hardness, wear resistance, and toughness, often found in the aerospace, oil & gas, and heavy machinery sectors.

Tool Steels: For tools, dies, and molds that need to be tough yet machinable.

Stainless Steels: For improved corrosion resistance and material uniformity, especially in components used in harsh environments.

Applications of Normalizing in Castings and Forgings

Normalizing is applied to a wide range of castings and forgings across various industries to ensure that components meet the required mechanical properties and performance standards. Some key applications include:

Automotive Industry: Engine components, crankshafts, gears, suspension components, and structural parts that need improved strength, toughness, and fatigue resistance.

Construction Machinery: Structural components and engine parts that require uniform strength and high toughness.

Heavy Machinery: Components such as gears, shafts, and frames used in mining, construction, and agricultural machinery that are subjected to high mechanical stresses.

Tooling & Dies: Manufacturing tools, molds, and dies that require enhanced durability and the ability to withstand high wear and mechanical stress.

Oil & Gas: Parts used in drilling and exploration equipment that must endure extreme environmental conditions while maintaining dimensional stability and strength.

Energy Sector: Components used in power plants, turbines, and other energy-producing equipment that require uniform material properties for high-pressure and high-temperature applications.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi