Overview of Salt Bath Heat Treatment Process

Salt bath heat treatment involves the immersion of metal parts in a bath of molten salts at a precisely controlled temperature. This process allows for uniform heating, rapid and controlled quenching, and improved metallurgical properties. The key phases of the salt bath heat treatment process are as follows:

1. Salt Bath Heating:

The metal components are immersed in a molten salt bath at the required austenitizing temperature, typically ranging from 850°C to 1,200°C (1,562°F to 2,192°F), depending on the material being treated and the desired properties.

The molten salt acts as an efficient medium for transferring heat to the parts, ensuring uniform temperature distribution and preventing thermal gradients. This uniformity reduces the risk of warping or distortion, which can occur with uneven heating in traditional furnaces.

2. Soaking (Holding) Period:

Once the desired temperature is reached, the components are held at that temperature for a specific duration. This soaking period ensures that the part reaches the required microstructure throughout the material, such as a fully austenitic phase in steel, which is critical for subsequent quenching and hardening.

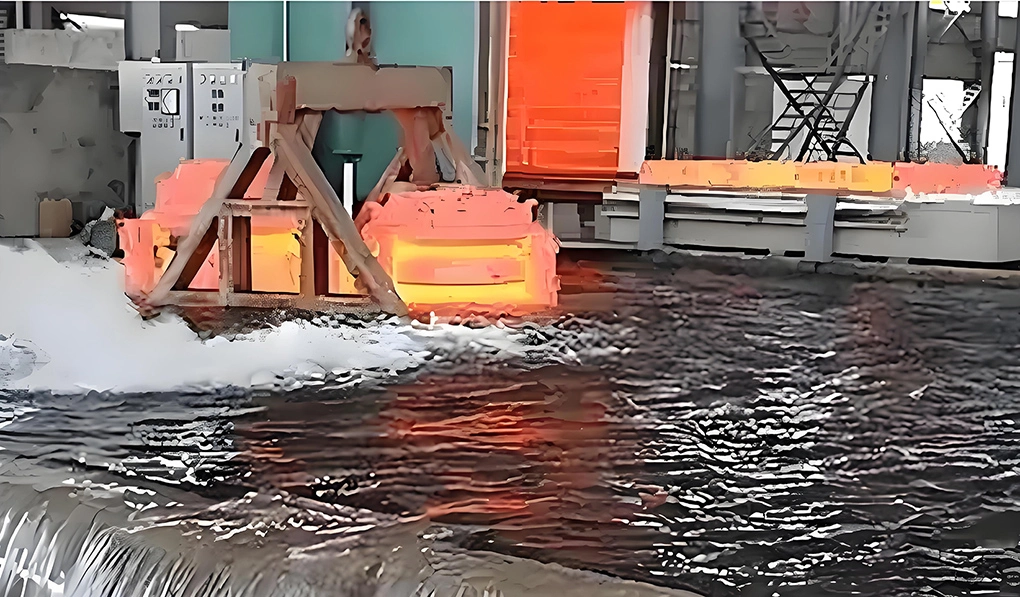

3. Quenching (Cooling) in Molten Salt:

After heating, the parts are rapidly quenched in a different salt bath at a lower temperature or in the same bath after it has been cooled slightly.

Salt bath quenching provides rapid cooling, which is critical for hardening the material. The salt medium offers faster quenching compared to air, leading to improved hardness and surface finish.

4. Post-Treatment (Optional):

In some cases, additional processes such as tempering, stress relieving, or surface hardening can be applied after salt bath heat treatment to achieve the final mechanical properties.

Post-treatment may also include a controlled cooling process to relieve any residual stresses and enhance the dimensional stability of the part.

Types of Salt Baths Used in Heat Treatment

Several types of molten salts are used in salt bath heat treatment, each offering distinct advantages based on the material being treated and the desired results:

· Chloride-based Salt Baths:

These are the most common salts used in heat treatment, offering excellent heat transfer and high thermal stability. Common salts in this category include sodium chloride (NaCl) and potassium chloride (KCl). They are ideal for quenching steel and alloys.

· Nitrate-based Salt Baths:

Nitrate salts, such as sodium nitrate (NaNO3) and potassium nitrate (KNO3), are often used for specific alloy steels, offering faster cooling rates and superior control over the quenching process. Nitrate baths are particularly useful for carburizing or carbonitriding processes.

· Bromide-based Salt Baths:

These salts are less commonly used but provide excellent quenching capabilities and can be used for materials requiring high-temperature treatments and high precision.

· Mixed Salt Baths:

Sometimes a mixture of salts is used to achieve the desired heat transfer properties, cooling rates, and temperature stability required for specific applications.

Advantages of Salt Bath Heat Treatment for Castings and Forgings

Salt bath heat treatment provides a variety of benefits, making it an ideal choice for many industrial applications, particularly for castings and forgings. Some of the key advantages include:

1. Uniform Heating and Temperature Control:

Salt baths provide more uniform heating compared to traditional furnaces, reducing the risk of thermal gradients that could cause distortion, cracking, or uneven hardness. This is especially important for large or complex castings and forgings, which may be prone to warping in traditional methods.

2. Faster Heating and Quenching:

3. Improved Hardness and Surface Quality:

Salt bath quenching produces a more uniform hardening of the material, leading to a more consistent hardness profile across the entire part. The rapid cooling provided by salt baths also results in a smoother surface finish compared to air cooling, minimizing the need for additional surface finishing processes.

4. Reduced Oxidation and Decarburization:

Salt baths can minimize oxidation and decarburization, which are common problems when heat treating materials in air. The salt bath creates an inert environment that reduces the formation of scale and preserves the material’s surface integrity, ensuring a high-quality finished product.

5. Reduced Distortion and Stress:

The controlled and uniform cooling process in salt bath heat treatment helps reduce the risk of warping or cracking in complex or thin-walled castings and forgings. The quenching process can be tailored to the material’s specific needs, minimizing residual stresses and preventing distortion during the treatment.

6. Energy Efficiency:

7. High-Quality Surface Finish:

Because the cooling rate is uniform and fast, the salt bath process reduces the occurrence of surface imperfections such as scaling or pitting, resulting in a cleaner surface finish. This is particularly beneficial for high-precision parts.

8. Flexibility in Treatment Parameters:

The temperature and cooling rates in salt bath heat treatment can be precisely controlled, allowing for a high degree of customization based on the material and desired mechanical properties. This makes salt bath heat treatment ideal for a wide range of alloys, from simple carbon steels to high-alloy tool steels and castings.

Applications of Salt Bath Heat Treatment for Castings and Forgings

Salt bath heat treatment is widely used in industries that require precision, high performance, and consistency for castings and forgings. Typical applications include:

1. Automotive Industry:

· Gears and Transmission Parts:

Salt bath heat treatment is commonly used for hardening automotive gears, shafts, and transmission components, improving their wear resistance and fatigue strength while maintaining dimensional stability.

· Suspension Components and Axles:

Components like control arms, axle shafts, and suspension springs benefit from improved strength and toughness through salt bath heat treatment.

2. Heavy Equipment and Mining:

· Wear Parts:

Salt bath quenching is often used for producing wear-resistant parts such as mining drills, crushing jaws, and other high-strength components.

· Cylinders, Pins, and Bushings:

Salt bath heat treatment ensures durability and wear resistance for components exposed to harsh operating conditions in heavy machinery and mining equipment.

3. Tooling and Molds:

· Die Castings and Mold Inserts:

Tool steels and other alloys used for dies and molds are often treated with salt bath quenching to achieve the desired hardness and wear resistance, ensuring long tool life and high precision in production.

· Cutting Tools and Dies:

Cutting tools such as drills, end mills, and dies undergo salt bath heat treatment to achieve superior hardness, wear resistance, and toughness.

4. General Industrial Applications:

· Fasteners and Structural Components:

Salt bath heat treatment is commonly used for small to medium-sized components like bolts, nuts, and structural parts that require increased strength, hardness, and corrosion resistance.

· Valves and Pump Components:

Salt bath quenching improves the mechanical properties of components such as valve bodies, pump parts, and other critical components in fluid handling systems.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi