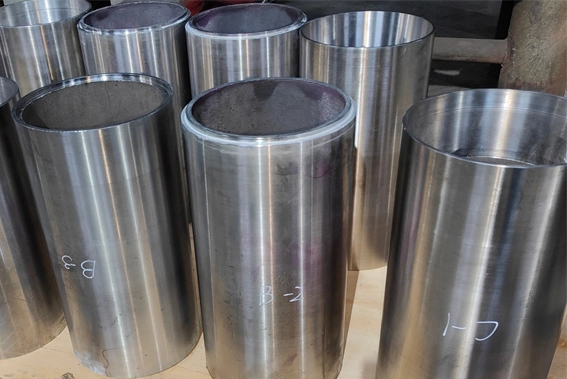

Advantages of Ductile Iron Sand Castings

High Strength and Toughness: Ductile iron has higher tensile strength and better impact resistance than traditional gray iron, making it suitable for parts subject to heavy stress and shock loading.

Ductility: Unlike other types of cast iron, ductile iron exhibits greater elongation before failure, providing better ability to deform without breaking.

Corrosion Resistance: Ductile iron has better resistance to corrosion compared to conventional cast iron, making it suitable for harsh environments.

Machinability: Despite its high strength, ductile iron is relatively easy to machine, which is beneficial in producing complex parts.

Cost-Effective: Ductile iron sand casting is a cost-effective method of producing durable and high-strength components, especially for medium- to large-scale production runs.

Applications of Ductile Iron Sand Castings

Ductile iron sand castings are widely used across various industries due to their high strength, durability, and versatility. Below are some key applications:

1. Automotive Industry

Ductile iron is extensively used in the automotive sector for manufacturing components that require both strength and impact resistance. Its ability to absorb shock and handle high stress makes it ideal for critical automotive parts.

Suspension Components: Control arms, brackets, steering knuckles, and spindles are made from ductile iron to provide the necessary strength and durability to withstand road stresses.

Engine Parts: Crankshafts, cylinder heads, flywheels, and piston rods are often made from ductile iron for better performance in high-pressure and high-temperature environments.

Brake Rotors and Drums: Ductile iron is a common material for brake rotors, discs, and drums, as it provides excellent thermal conductivity, wear resistance, and strength to withstand the mechanical demands of braking systems.

Benefits in Automotive:

Impact Resistance: The high impact resistance of ductile iron is ideal for parts exposed to dynamic loads and shocks.

Thermal Resistance: Ductile iron is capable of withstanding high temperatures, which is crucial for engine components and brake systems.

Durability and Longevity: Parts made from ductile iron have long lifespans, even under heavy mechanical stresses.

2. Heavy Machinery and Construction Equipment

Ductile iron sand castings are widely used in the heavy machinery and construction industries to produce durable, high-strength parts capable of handling the demanding conditions of heavy-duty equipment.

Excavator and Loader Parts: Components like bucket teeth, brackets, frames, and gearboxes are made from ductile iron for its ability to resist wear and handle shock loading in the construction and mining sectors.

Crane Components: Booms, rotating parts, and gearing systems used in cranes and lifting equipment are often cast in ductile iron to provide both strength and impact resistance.

Pumps and Valves: Pump housings, impellers, and valve bodies made from ductile iron are essential for water, oil, and slurry pumping systems in construction and infrastructure projects.

Benefits in Heavy Machinery:

Wear Resistance: Ductile iron is resistant to wear and abrasion, making it ideal for machinery that operates in harsh conditions.

Strength: It provides the mechanical strength necessary for heavy-duty equipment to function reliably.

Impact Absorption: The shock resistance of ductile iron ensures machinery components can withstand sudden impacts.

3. Power Generation

In power generation systems, ductile iron is used for producing parts that need to withstand extreme temperatures, high pressures, and the continuous mechanical stress encountered in power plants.

Turbine and Generator Components: Parts such as turbine casings, pump housings, and generator housings are often made from ductile iron for its strength and thermal resistance.

Valve Bodies and Fittings: Ductile iron is commonly used for producing valve bodies, flanges, and pipe fittings that must endure high pressure and temperature, especially in steam and hydroelectric plants.

Pressure Vessels: Boiler components, including pressure vessels and flange connections, are often cast from ductile iron to provide the required strength to handle high-pressure steam.

Benefits in Power Generation:

High Temperature Resistance: Ductile iron components can withstand the extreme temperatures typical in power plants, such as those found in turbines and boilers.

Strength and Durability: The material’s ability to endure mechanical stresses is essential for the demanding environments in power generation systems.

Corrosion Resistance: Ductile iron can resist corrosion from exposure to high-temperature steam and other aggressive fluids in power plants.

4. Water and Wastewater Treatment

Ductile iron is extensively used in the water and wastewater treatment industry due to its strength, corrosion resistance, and ability to handle high pressures. Components for piping systems, valves, and pumps are often made from ductile iron.

Pipes and Fittings: Water pipes, stormwater drains, and sewer systems are commonly made from ductile iron for its durability and resistance to corrosion from soil and moisture exposure.

Valves: Gate valves, check valves, and ball valves made from ductile iron are critical for regulating water flow in municipal and industrial water systems.

Pump Components: Pump bodies, impellers, and diffusers are often cast in ductile iron due to its resistance to wear and corrosion.

Benefits in Water Treatment:

Corrosion Resistance: Ductile iron is resistant to the corrosion that can occur when exposed to water and wastewater, ensuring long service life for pipelines and fittings.

Pressure Resistance: Ductile iron’s ability to withstand high pressure makes it ideal for use in water systems, where pipes and valves must endure significant internal pressures.

Durability: The material’s durability ensures that water and wastewater systems remain functional for many years, even under harsh conditions.

5. Agricultural Equipment

In agriculture, ductile iron sand castings are used for components that must handle the rough working conditions and mechanical loads often encountered in farming and forestry equipment.

Tractor Parts: Chassis components, axle housings, and brackets are cast from ductile iron to provide the strength and impact resistance needed for agricultural machinery.

Harvesting Equipment: Parts like spindles, gearing, and rotors used in harvesters and combine harvesters are made from ductile iron to withstand wear from constant use and exposure to soil and plant material.

Farm Implements: Plow bodies, disk harrow blades, and wheel hubs are commonly made from ductile iron for its combination of strength and durability.

Benefits in Agriculture:

Durability: Ductile iron’s toughness allows it to endure the rigorous conditions found in agricultural applications.

Impact Resistance: It can absorb shock and resist mechanical stress, making it ideal for parts exposed to rough terrain and sudden movements.

Wear Resistance: The material’s ability to resist wear ensures that agricultural machinery operates efficiently for longer periods.

6. Industrial Applications

Ductile iron sand castings are used in a wide range of industrial applications where strength, toughness, and corrosion resistance are important for the longevity and reliability of critical components.

Machine Parts: Machine frames, supports, and shafts in industrial machinery are made from ductile iron to provide strength and absorb vibrations.

Roots Blower Parts: Housings, Side Plates, End Plates, Rotors are made from ductile iron.

Structural Components: Brackets, clamps, and supporting frames in industrial applications benefit from the mechanical properties of ductile iron.

Gearboxes: Components of industrial gearboxes, including gear casings and housing parts, are made from ductile iron for its strength and resistance to wear under high loads.

Benefits in Industrial Applications:

Strength: The material provides the strength needed for structural parts and machinery components in industrial settings.

Vibration Dampening: Ductile iron absorbs vibrations, making it useful in components that must reduce noise and wear.

Machinability: Despite its strength, ductile iron is relatively easy to machine, allowing for complex parts to be produced cost-effectively.

Conclusion

Ductile iron sand castings offer a unique combination of strength, toughness, and ductility, making them an ideal choice for a wide variety of industries. From automotive components to heavy machinery, power generation, water systems, and agricultural equipment, ductile iron’s versatility and performance make it a preferred material for applications that require durable, high-performance parts. The casting process allows manufacturers to produce complex parts at relatively low cost, making ductile iron an attractive option for both small- and large-scale production runs.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi