Applications of CNC Milling for Castings and Forgings

1. Precision Machining:

Achieves tight tolerances and intricate geometries on cast and forged parts.

Common in automotive, aerospace, medical, and industrial machinery sectors.

2. Surface Finishing:

3. Hole Drilling and Tapping:

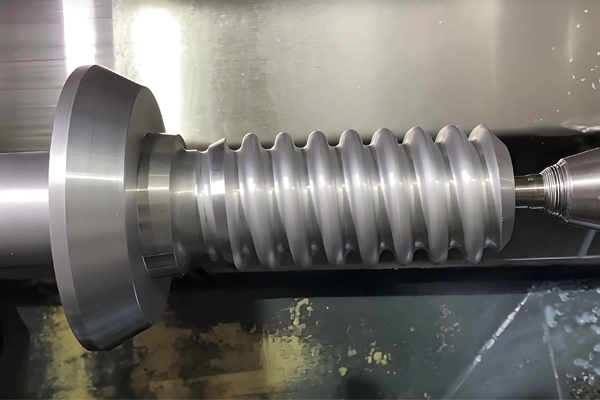

4. Contour Milling:

5. Resurfacing and Trimming:

Machines Used for CNC Milling

1. Vertical Machining Centers (VMC):

Ideal for flat or slightly contoured components.

Commonly used for operations like drilling, tapping, and face milling.

2. Horizontal Machining Centers (HMC):

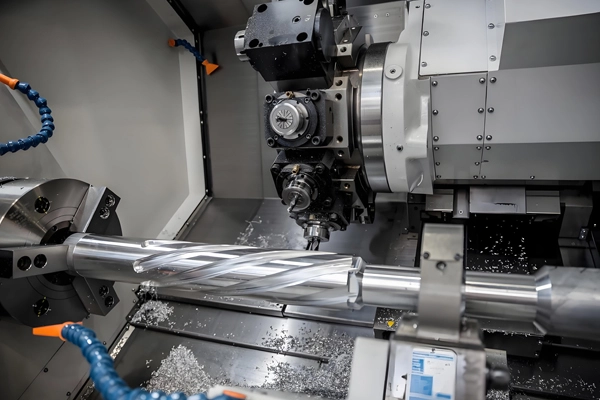

3. 5-Axis CNC Mills:

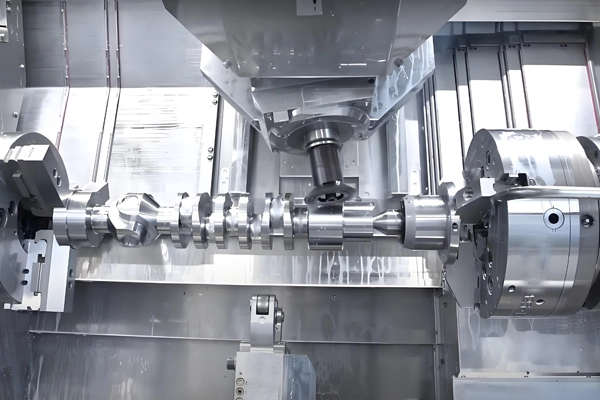

4. Specialized CNC Lathes with Milling Attachments:

5. High-Speed CNC Mills:

Dimensional Inspection Measures

1. Manual Inspection Tools:

2. Coordinate Measuring Machines (CMM):

3. Optical Comparators:

4. Laser Scanners and 3D Probes:

5. Surface Roughness Testers:

6. Gauge Blocks and Fixtures:

Inspection Reports

1. First Article Inspection (FAI):

2. Statistical Process Control (SPC):

3. Material Test Reports (MTR):

4. Dimensional Inspection Reports:

5. Non-Destructive Testing (NDT) Reports:

Quality Control Measures

1. Pre-Machining Quality Checks:

2. In-Process Monitoring:

3. Post-Machining Inspections:

4. Tool Condition Monitoring:

5. Quality Management Systems (QMS):

6. Traceability:

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi