1. Water Glass Sand Casting Process

The Water Glass Sand Casting process is similar to traditional sand casting but uses sodium silicate (also known as water glass) as the binder. The steps involved in water glass sand casting are as follows:

a. Pattern Creation

Pattern Design: As with other casting processes, the first step involves designing a pattern of the part to be cast. The pattern is typically made from metal, wax, or plastic, and it is created in the shape of the desired casting.

Pattern Materials: The pattern can be made of any material suitable for the specific casting process, including aluminum, steel, or other metals, as well as non-metal materials like wax for investment casting.

b. Sand Preparation

Sodium Silicate Binder: In water glass sand casting, sodium silicate (a mixture of sodium oxide and silica) is used as the binder for the sand. The binder is usually mixed with fine silica sand to create a sand mixture that can hold the shape of the mold.

Mixing the Sand: The silica sand is mixed with the sodium silicate solution and sometimes a hardening agent (like carbon dioxide gas or an acid) to ensure that the mixture hardens and can withstand the molten metal during pouring.

Curing Process: The sand mixture is hardened through a curing process, where carbon dioxide gas or another hardening agent is introduced. The reaction between the sodium silicate and carbon dioxide causes the sand to harden and solidify, forming the mold.

c. Mold Formation

Mold Building: Once the sand mixture is ready, it is packed around the pattern to form the mold. The pattern is typically made in two parts: the cope (top half) and the drag (bottom half). A core may also be used to create internal cavities in the casting.

Hardening the Mold: The mold is allowed to harden completely before being removed from the pattern. The carbon dioxide treatment causes the mold to become rigid, making it strong enough to handle the molten metal during casting.

d. Pouring the Molten Metal

Metal Melting: The metal (typically steel, iron, or non-ferrous alloys) is heated to the appropriate pouring temperature in a furnace. The metal must be heated sufficiently to be poured into the mold, typically at temperatures between 1,400°C (2,552°F) to 1,600°C (2,912°F) for ferrous metals, or lower for non-ferrous alloys.

Pouring: The molten metal is carefully poured into the prepared water glass sand mold. The mold should be pre-heated to avoid thermal shock, although water glass molds can withstand high temperatures and thermal gradients better than traditional sand molds.

e. Cooling and Solidification

Cooling: After pouring, the metal is allowed to cool and solidify in the mold. Water glass sand molds typically cool at a relatively controlled rate due to the strong bond between the sand and the binder, resulting in minimized shrinkage and better dimensional accuracy.

Solidification: As the molten metal cools, it solidifies, taking the shape of the mold cavity. The solidified metal part will often shrink slightly as it cools, but this shrinkage is typically minimized in water glass sand casting.

f. Mold Removal and Cleaning

Mold Breaking: Once the metal has cooled and solidified, the mold is broken apart to reveal the finished casting. The water glass sand mold is brittle and can be easily broken up, allowing for easy removal of the casting.

Cleaning: The casting is cleaned to remove any remaining sand or mold debris. The surface is usually smoother than traditional sand castings, which reduces the need for extensive post-casting finishing.

g. Inspection and Post-Processing

Machining: After the casting has been cleaned, it may undergo additional machining to achieve tight tolerances or specific surface finishes.

Heat Treatment: Depending on the material and application, the casting may undergo heat treatment (such as annealing, quenching, or tempering) to improve its mechanical properties, such as strength, hardness, or toughness.

2. Applications of Water Glass Sand Casting

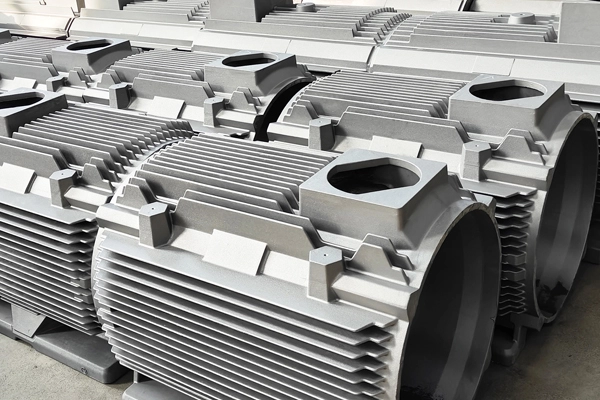

Water glass sand casting is particularly advantageous for applications that require high precision, fine surface finishes, and the ability to produce complex geometries. Below are some of the main industries and applications for water glass sand casting:

a. Automotive Industry

Engine Components: Water glass sand casting is used to create engine blocks, cylinder heads, intake manifolds, and other critical engine components that require strength, precision, and durability.

Transmission and Drivetrain Parts: Precision casting of parts like gears, shafts, and housings that need to endure high stress and pressure.

Suspension and Steering Components: Parts like control arms, knuckles, and brackets used in automotive suspension and steering systems.

b. Power Generation

Turbine Components: Components for steam turbines, gas turbines, and hydroelectric turbines, which require high performance and reliability, are commonly cast using water glass sand casting.

Valve Bodies and Pump Parts: These parts often require tight tolerances and resistance to corrosion, which is achievable using the water glass sand casting process.

c. Marine Industry

Propeller Housings: The marine industry uses water glass sand casting for producing propeller housings, shafts, and other components exposed to seawater, where high resistance to wear and corrosion is essential.

Pump and Valve Components: Water glass casting is used to create pump bodies, valve components, and other marine machinery parts that need to endure harsh environments.

d. Oil and Gas

Drill Bits and Components: Castings for oil and gas exploration, such as drill bits and parts for drilling rigs, are often made using water glass sand casting due to its ability to produce strong, precise, and durable components.

Pipe Fittings: High-quality, precision castings for pipe fittings, flanges, and other pipeline components that need to withstand high pressure and corrosive environments.

e. Industrial Equipment

Heavy Machinery Components: Components for construction machinery, mining equipment, and industrial tools benefit from water glass sand casting due to the precision and strength it provides.

Machine Tool Parts: Castings for machine beds, bases, and other parts used in heavy-duty industrial machinery are made using water glass sand casting for enhanced dimensional accuracy and strength.

f. Custom Castings

Prototype and Low-Volume Production: Water glass sand casting is often used for prototyping or small-batch production of custom parts that require a fine surface finish and tight tolerances.

Complex Geometries: Due to its ability to handle complex shapes, water glass sand casting is used in applications where intricate geometries and fine details are required, such as in some custom, high-end products.

3. Advantages of Water Glass Sand Casting

High Dimensional Accuracy: Water glass sand casting produces parts with excellent dimensional accuracy, which reduces the need for extensive post-casting machining.

Superior Surface Finish: The process results in castings with a smoother surface finish compared to traditional sand casting, reducing the need for polishing or other finishing steps.

Strong Mold: The sodium silicate binder forms a strong mold that is capable of withstanding the pouring of molten metal without deformation.

Environmental Benefits: Water glass (sodium silicate) is an inorganic binder that is environmentally friendly, and the process produces less waste compared to other casting methods that use organic binders.

High Precision: Water glass sand casting can produce small and precise parts, including complex internal and external features, with minimal shrinkage and excellent resolution of fine details.

Reduced Gas Porosity: The curing mechanism for the sand mold reduces the likelihood of gas porosity, improving the overall quality of the casting.

Why Choose Walkson for Your Glass Sand Casting Project?

Unmatched Large-Scale Casting Capability: We are equipped to produce among the world’s largest and most complex water glass sand castings, with a demonstrated capacity for single-piece castings weighing up to 80 tons. This allows us to deliver massive, high-integrity components for the most demanding heavy equipment and infrastructure projects.

True Vertical Integration: Walkson is your single-source solution. From initial design for manufacturability (DFM) assistance and precision sand casting, through critical heat treatment and final CNC machining, we control the entire manufacturing process. This integrated approach guarantees seamless workflow, superior quality consistency, and significant time and cost savings for you.

Relentless Commitment to Quality: Every casting undergoes our rigorous, multi-stage Quality Control protocol. Utilizing advanced Non-Destructive Testing (NDT) methods such as ultrasonic and radiographic inspection, we verify internal soundness and structural integrity. Our commitment ensures that every component not only meets but often exceeds stringent international standards and your specific performance requirements.

Proven Expertise Across Critical Industries: Leveraging decades of specialized experience, we have built a deep understanding of the unique challenges in sectors like automotive, marine, oil & gas, and heavy equipment manufacturing. This industry-specific knowledge allows us to anticipate needs, recommend optimal materials and processes, and deliver castings that perform reliably in the toughest operating environments.

Materials we can do but not limited to:

carbon steels, alloy steels, stainless steels and duplex steels, high manganese steel, Cr-Mo steel, high chrome white iron such as AISI4140(42CrMo4), AISI4135(35CrMo), WCB、LCB、WC9、CA15、C12A, CF3、CF8M、CN7M, 5A, 6A, F304, F316, F51, etc

Products:

Heavy steel castings, max weight 80ton casting per pc, SAG rod mill liners, Ground engage tool(G.E.T), rigging components, excavator undercarriage components such as sprockets/idler/track pads, etc.

Eeavy engineering parts such as walking frame, walking cam for dragline excavator, slurry pump parts and other wear-resistant components used on crusher equipment, pump, valve components, check valve, globel valve, gate valve, butterfly valve, ball valve, safety valve, etc.,

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi