Applications of CNC Drilling and Tapping for Castings and Forgings

1. Hole Creation:

2. Thread Tapping:

3. Counterboring and Countersinking:

4. Spot Drilling:

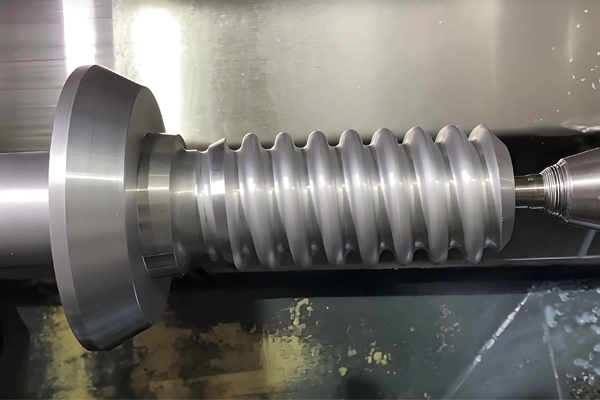

5. Specialized Features:

6. High-Volume Production:

Machines Used for CNC Drilling and Tapping

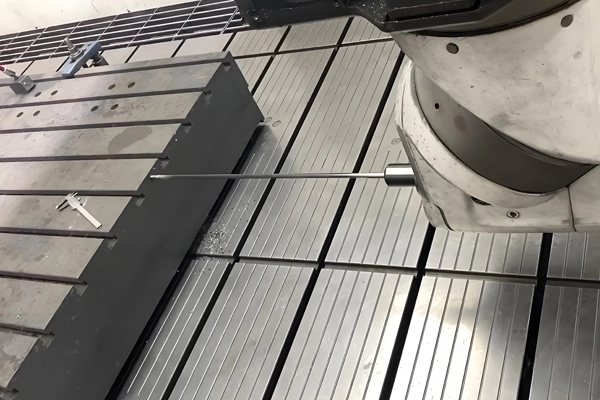

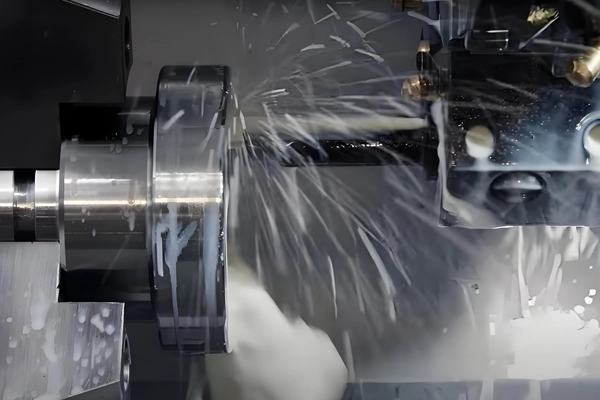

1. CNC Drilling Machines:

2. CNC Tapping Centers:

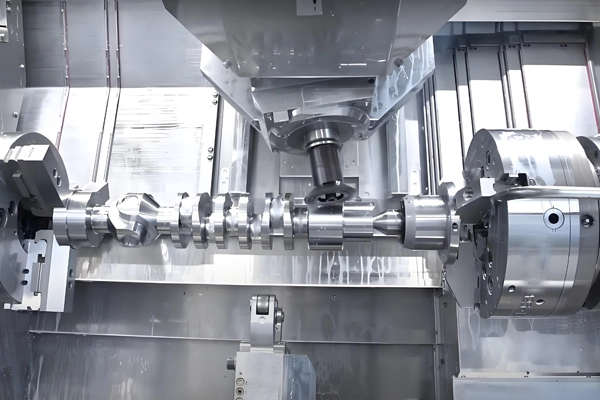

3. Vertical and Horizontal Machining Centers:

4. Multi-Spindle CNC Drilling and Tapping Machines:

5. 5-Axis CNC Machines:

6. Radial Drilling Machines:

Dimensional Inspection Measures

1. Plug Gauges and Ring Gauges:

2. Thread Gauges:

3. Coordinate Measuring Machines (CMM):

4. Depth Gauges:

5. Optical Comparators:

6. Surface Finish Testers:

7. Bore Scopes:

Inspection Reports

1. First Article Inspection (FAI):

2. Thread Inspection Reports:

3. Geometric Dimensioning and Tolerancing (GD&T) Reports:

4. Material Test Reports (MTR):

5. Depth Verification Reports:

6. Dimensional Inspection Reports:

Quality Control Measures

1. Pre-Machining Inspection:

2. Tool Monitoring and Maintenance:

3. In-Process Monitoring:

4. Deburring:

5. Post-Machining Inspection:

6. Non-Destructive Testing (NDT):

7. Standards Compliance:

8. Traceability:

Advantages of CNC Drilling and Tapping for Castings and Forgings

1. High Precision:

2. Repeatability:

3. Versatility:

4. Efficiency:

5. Cost-Effectiveness:

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi