Advantages of Alkaline Phenolic Resin Sand Casting

High Mold Strength: Alkaline phenolic resin bonds well with sand, providing strong and durable molds that can withstand high temperatures during the casting process.

Dimensional Accuracy: The resin-based molds result in castings with high dimensional accuracy, reducing the need for post-casting machining.

Surface Finish: This process can produce castings with smoother surface finishes compared to traditional sand casting, which reduces the need for finishing work.

Thermal Stability: Alkaline phenolic resins offer excellent thermal stability, making them suitable for casting metals at high temperatures.

Environmental Compatibility: The alkaline phenolic resin sand casting process can produce molds with less volatile organic compound (VOC) emissions compared to other resin systems, making it more environmentally friendly.

Applications of Alkaline Phenolic Resin Sand Castings

Alkaline phenolic resin sand castings are widely used across various industries where high-quality, high-precision metal components are required. Some of the major applications include:

1. Automotive Industry

Alkaline phenolic resin sand castings are used to produce critical automotive components that require high strength, precision, and durability.

Engine Components: Cylinder heads, engine blocks, and valve bodies are often cast using alkaline phenolic resin molds for their high thermal resistance and dimensional accuracy.

Transmission Parts: Gear housings, shafts, clutch parts, and bearings benefit from the strength and precise finish that alkaline phenolic resin sand casting offers.

Suspension Components: Control arms, brackets, and knuckles made from aluminum or steel alloys are cast using this process to ensure high strength and dimensional consistency.

Benefits in Automotive:

High Strength: Ensures automotive parts can withstand the high pressures and temperatures of engine systems.

Precision: Reduces the need for machining, ensuring parts fit precisely.

Durability: Resists wear and corrosion, enhancing the lifespan of critical components.

2. Industrial Equipment and Machinery

Alkaline phenolic resin sand castings are ideal for manufacturing parts used in industrial equipment and machinery, where high strength, durability, and precision are essential.

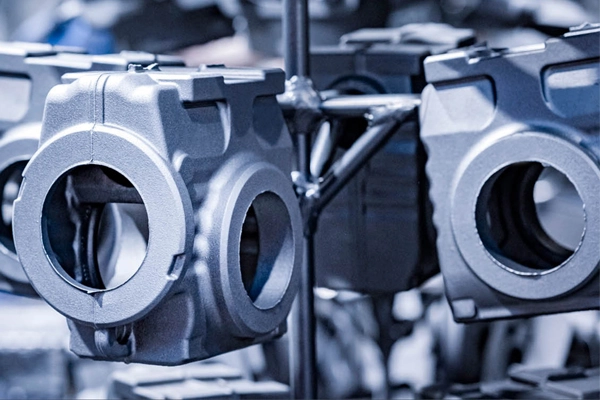

Pumps and Valves: Pump housings, valve bodies, flanges, and impellers made from cast steel or cast iron alloys are commonly produced using alkaline phenolic resin molds.

Turbine Components: Turbine rotors, blades, and discs for power generation and aerospace applications are cast using this process to achieve both high precision and thermal stability.

Pressure Vessels: Components such as pressure vessel heads, tubes, and flanges made of steel alloys are commonly cast with alkaline phenolic resin sand.

Benefits in Industrial Equipment:

High Precision: Achieves tight tolerances, reducing the need for post-casting machining.

Heat Resistance: Castings can withstand high temperatures, making them suitable for high-heat industrial applications like turbines and valves.

Wear Resistance: Ideal for parts exposed to mechanical wear and corrosion, ensuring extended service life.

3. Oil and Gas Industry

The oil and gas industry relies heavily on casting technologies for the manufacture of heavy-duty components that need to withstand harsh environmental conditions such as extreme pressure, temperature, and corrosion.

Valve Bodies: Gate valves, check valves, and ball valves used in pipeline systems are often cast using alkaline phenolic resin sand molds for their strength and dimensional precision.

Drill Bits: Drill heads and tool joints for offshore and onshore drilling rigs are commonly produced using this process to provide toughness and wear resistance.

Pump Casings: Pump housings, impellers, and shaft sleeves are cast from materials like stainless steel and cast iron for the durability required in petroleum extraction and transportation.

Benefits in Oil and Gas:

Corrosion Resistance: Parts used in oil and gas extraction often face corrosive conditions; alkaline phenolic resin sand casting ensures longevity and performance.

Strength Under Pressure: Cast components need to withstand high pressures and impacts, which is a core benefit of this casting method.

Dimensional Accuracy: The need for precise dimensions in oil and gas parts is met by the accurate molding capabilities of alkaline phenolic resin casting.

4. Heavy Equipment and Construction

For heavy machinery and construction equipment, where parts must endure extreme stresses and harsh operating conditions, alkaline phenolic resin sand castings provide the necessary strength, durability, and performance.

Excavator Components: Buckets, frames, and arm components used in excavators and bulldozers benefit from the tough, durable qualities of this casting process.

Crane Parts: Hoist components, sprockets, and gearboxes used in cranes are made from castings that offer both high strength and resilience to wear.

Tractor and Agricultural Parts: Chassis parts, housings, and engine components are commonly made from steel or cast iron alloys using alkaline phenolic resin sand casting.

Benefits in Heavy Equipment:

Durability: Components need to endure heavy loads and frequent operation; this casting method provides the necessary strength.

Toughness: Resistance to wear, impact, and corrosion is essential for machinery working in rough environments, and alkaline phenolic resin sand casting ensures these properties.

Cost-Effectiveness: High-strength parts with complex geometries can be produced more economically than alternative manufacturing methods like machining from solid stock.

5. Marine Industry

In the marine sector, where resistance to corrosion, high strength, and durability are crucial for parts exposed to harsh marine environments, alkaline phenolic resin sand casting is widely used.

Propeller Parts: Boat propellers, rudder blades, and shaft couplings are commonly made using this casting process.

Engine Components: Cylinder heads, piston housings, and valve covers in marine engines benefit from the high thermal stability and corrosion resistance of the resin.

Structural Marine Components: Marine winches, mounting brackets, and housings for boats and ships are cast from aluminum or steel using alkaline phenolic resin sand for enhanced performance and corrosion resistance.

Benefits in Marine:

Corrosion Resistance: The marine environment demands components that resist corrosion from saltwater exposure, which is achieved with alkaline phenolic resin sand casting.

Strength and Durability: Parts must withstand mechanical stress, and this casting process provides the durability required for marine applications.

Precision: Marine components need to fit together precisely, and the high dimensional accuracy of this casting method meets this need.

Conclusion

Alkaline phenolic resin sand casting offers significant advantages in producing high-precision, durable, and heat-resistant components across a wide range of industries, including aerospace, automotive, oil and gas, industrial equipment, heavy machinery, and marine. This casting method provides the flexibility to create complex geometries, excellent surface finishes, and high-strength components while maintaining environmental compatibility and cost-effectiveness. With its ability to handle high thermal and mechanical stresses, alkaline phenolic resin sand casting is ideal for demanding applications where performance, precision, and longevity are paramount. With a commitment to excellence, Walksonn has established itself as a professional and reliable sand casting factory in China.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi