Process Overview:

1. Pattern Preparation: Similar to standard lost foam casting, a foam pattern is created to replicate the desired component.

2. Coating: The foam is coated with a refractory material to protect it during casting and ensure a high-quality surface finish.

3. Molding: The coated foam pattern is placed in a flask filled with unbonded sand.

4. Vacuum Application: A vacuum is applied to the mold cavity to remove air, stabilize the sand, and create a vacuum-sealed environment.

5. Casting: Molten metal is poured into the foam cavity. The vacuum assists in drawing the molten metal into intricate sections, improving mold filling.

6. Cooling and Finalization: Once solidified, the vacuum is released, and the casting is removed, followed by cleaning and finishing.

Applications of Vacuum Lost Foam Casting:

VLFC is especially suited for industries that demand high-precision, high-quality components. Common applications include:

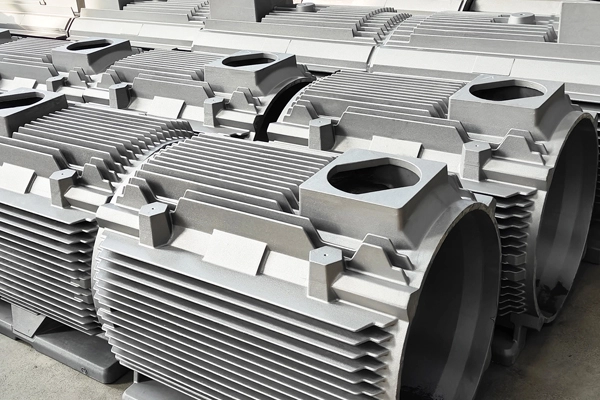

· Automotive: Lightweight and complex parts like engine blocks, crankcases, and exhaust manifolds.

· Power Generation: Turbine blades, housings, and generator components.

· Industrial Machinery: Precision castings for hydraulic components, pump housings, and valve bodies.

· Aerospace: High-performance parts requiring stringent quality standards.

· Defense: Complex, high-strength parts used in military applications.

Advantages of Vacuum Lost Foam Casting:

1. Enhanced Dimensional Accuracy: The vacuum reduces air entrapment, shrinkage, and porosity, ensuring high precision.

2. Improved Surface Finish: Reduced turbulence during pouring minimizes surface defects and provides smoother castings.

3. Ability to Cast Complex Shapes: The vacuum assists in filling intricate and thin-walled sections effectively.

4. Wide Material Compatibility: Applicable to various metals, including aluminum, steel, magnesium, and alloys.

5. Reduced Defects: The vacuum eliminates gas-related issues like blowholes and inclusions, resulting in higher-quality castings.

6. Environmental and Cost Benefits: The reusable sand and reduced need for secondary machining lower production costs and waste.

7. Structural Integrity: Produces denser castings with enhanced mechanical properties.

8. Increased Process Control: The vacuum environment allows for better regulation of casting conditions, ensuring consistent results.

The Vacuum Lost Foam Casting method combines the benefits of traditional lost foam casting with the precision and efficiency of vacuum technology. This makes it an ideal choice for industries seeking to manufacture lightweight, intricate, and high-performance components with uncompromising quality.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi