Quenching and Tempering Heat Treatment for Castings and Forgings

Introduction:

Quenching and tempering are essential heat treatment processes used to enhance the mechanical properties of steel and other ferrous alloys, making them ideal for high-performance applications where strength, toughness, and durability are critical. The process involves two main stages: quenching, where the material is rapidly cooled to achieve a hardened state, followed by tempering, where the material is reheated to reduce brittleness and enhance toughness. This combination of processes helps produce castings and forgings with the optimal balance of strength, hardness, and ductility.

Objective of Quenching and Tempering for Castings and Forgings

The primary objectives of quenching and tempering are:

Increase Hardness: Quenching enhances the hardness of the material, making it resistant to wear and improving its ability to withstand harsh mechanical stresses.

Improve Strength: Both quenching and tempering increase the material’s tensile strength, providing the ability to endure high levels of force and pressure without deformation.

Enhance Toughness and Ductility: Tempering is critical for reducing the brittleness caused by quenching, thereby improving the material’s toughness and ability to absorb impact without fracturing.

Achieve Desired Mechanical Properties: The process is tailored to achieve the specific mechanical properties required for the component's application, balancing strength, toughness, and fatigue resistance.

Improve Dimensional Stability: Quenching and tempering help reduce internal stresses within the material, ensuring dimensional stability during further processing or during operation in-service.

The Quenching and Tempering Process for Castings and Forgings

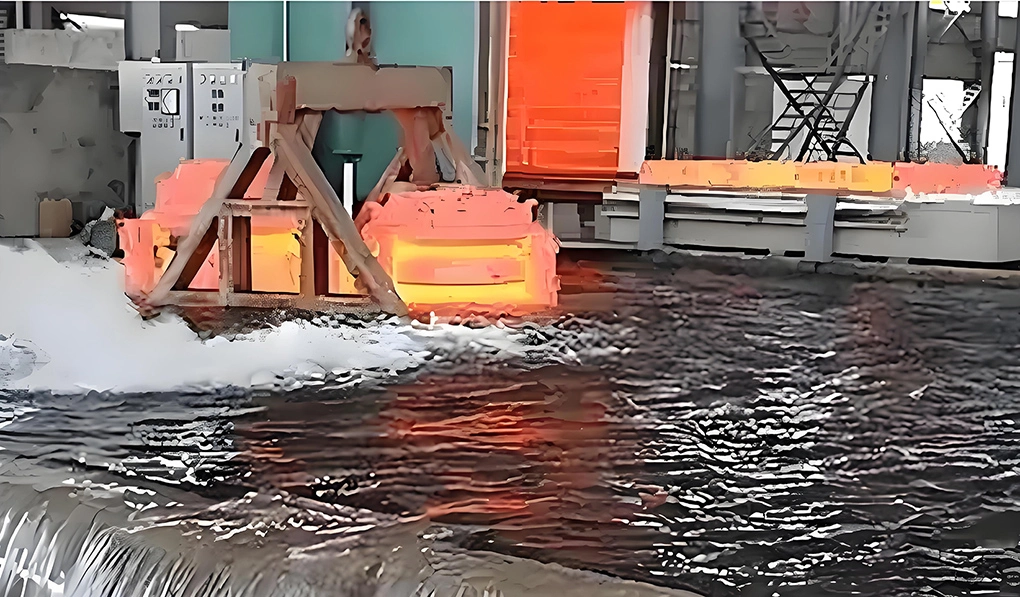

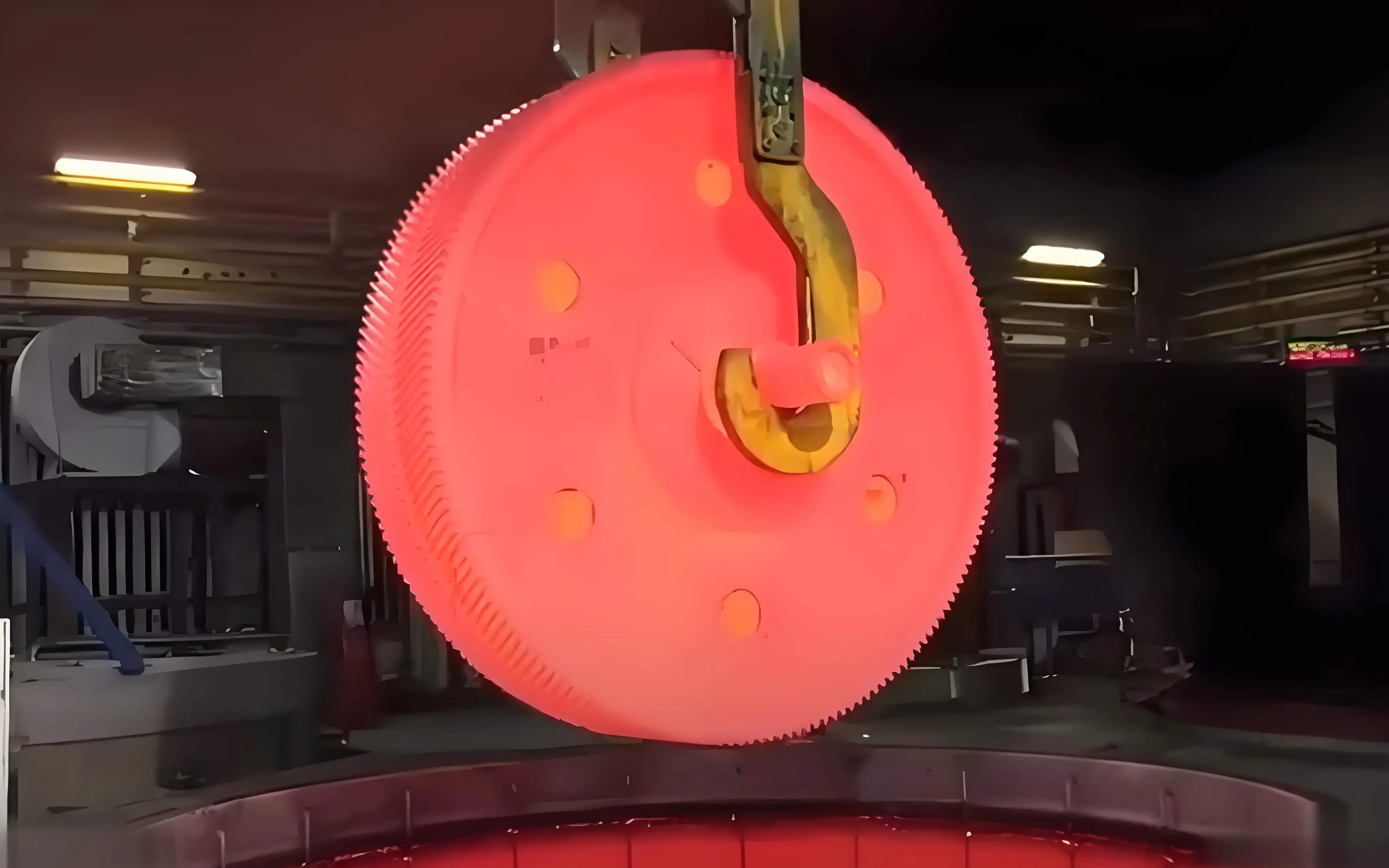

1. Quenching (Hardening):

The casting or forging is heated to a temperature above its critical range, typically 800°C to 900°C (1,470°F to 1,650°F), depending on the alloy and material requirements. This process causes the steel’s crystal structure to change into a martensitic phase, which is much harder than the original structure.

Once the material reaches the target temperature, it is rapidly cooled by immersion in a quenching medium, such as water, oil, or air. The rapid cooling locks the martensitic structure in place, resulting in increased hardness. However, this makes the material brittle, which is why tempering follows.

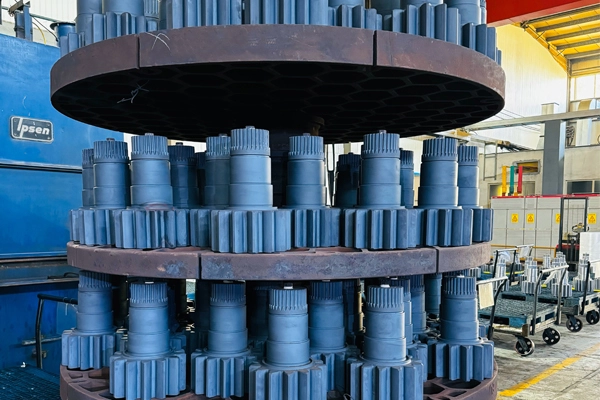

2. Tempering:

After quenching, the material is too hard and brittle for most applications. Tempering involves reheating the quenched material to a lower temperature (typically between 150°C and 650°C or 300°F to 1,200°F), then holding it at that temperature for a specified period. This process reduces the internal stresses created by quenching and restores some of the material’s ductility and toughness.

The temperature and time of tempering determine the final balance of hardness, strength, and toughness. Lower tempering temperatures tend to maintain higher hardness, while higher tempering temperatures improve toughness and ductility.

3. Cooling:

After tempering, the material is cooled at a controlled rate, typically in air. The cooling process after tempering helps solidify the modified microstructure, stabilizing the mechanical properties achieved.

Benefits of Quenching and Tempering for Castings and Forgings

1. Improved Hardness and Wear Resistance:

The quenching process increases the hardness of the material significantly, providing superior wear resistance. This makes quenching and tempering ideal for applications where the component will be subjected to high levels of friction, abrasion, or heavy mechanical loading.

2. Enhanced Strength:

3. Increased Toughness and Ductility:

While quenching creates a very hard material, it also makes it brittle. The tempering process restores ductility and reduces brittleness, improving the material’s ability to absorb impacts without cracking or fracturing. This is crucial for components subjected to dynamic loading or shock impacts.

4. Reduced Residual Stresses:

5. Customizable Mechanical Properties:

One of the key benefits of quenching and tempering is the ability to fine-tune the material properties to match specific requirements. By adjusting the quenching and tempering parameters (such as temperature and time), we can achieve the perfect balance of hardness, strength, and toughness for the end application.

6. Improved Fatigue Resistance:

Components treated with quenching and tempering exhibit enhanced fatigue resistance, which is essential for parts that experience repeated cycles of loading and unloading. This makes the process ideal for automotive, aerospace, and heavy machinery applications.

7. Dimensional Precision and Stability:

The reduction of internal stresses through tempering improves dimensional stability, which is essential for maintaining the precision and accuracy of castings and forgings, especially for components with tight tolerances.

Applications of Quenching and Tempering for Castings and Forgings

Quenching and tempering are widely used in industries where components must withstand heavy mechanical stresses, high wear, and extreme operating conditions. Some of the key applications include:

· Automotive Industry:

Gears, shafts, crankshafts, and suspension components that require high strength, wear resistance, and fatigue resistance for long-lasting performance.

· Construction Machinery:

Structural parts, arms and gear components that need to be both strong and tough under dynamic loading conditions.

· Heavy Machinery:

High-performance gears, axles, and components used in construction, mining, and agricultural machinery that are subjected to constant wear and heavy loads.

· Oil & Gas:

Tools, valves & pumps, and other components used in drilling, exploration, and extraction, where resistance to wear, high strength, and fatigue resistance are essential.

· Energy Sector:

Power generation equipment, turbine components, and valves that require high strength to withstand the pressures and temperatures encountered in power plants.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi