Objective of Nitrogen Hardening for Castings and Forgings

The primary goals of nitrogen hardening are:

Enhanced Surface Hardness: To significantly increase the surface hardness of components, improving wear resistance and reducing surface degradation under frictional conditions.

Corrosion Resistance: To improve the material’s resistance to corrosion and oxidation, which is essential in industries dealing with aggressive environments such as aerospace, energy, and marine applications.

Improved Fatigue Resistance: To enhance the fatigue strength of parts by creating a hardened surface layer that resists cracking and failure due to cyclic loading.

Maintained Core Toughness: To preserve the toughness and ductility of the core material while strengthening the surface, ensuring that the component performs optimally in both static and dynamic loading conditions.

Dimensional Stability: To avoid dimensional changes or distortion, making it ideal for precision parts that require tight tolerances and high-quality surface finishes.

The Nitrogen Hardening Process for Castings and Forgings

Nitrogen hardening involves several key steps that allow the material to achieve enhanced surface properties while maintaining the integrity of the core:

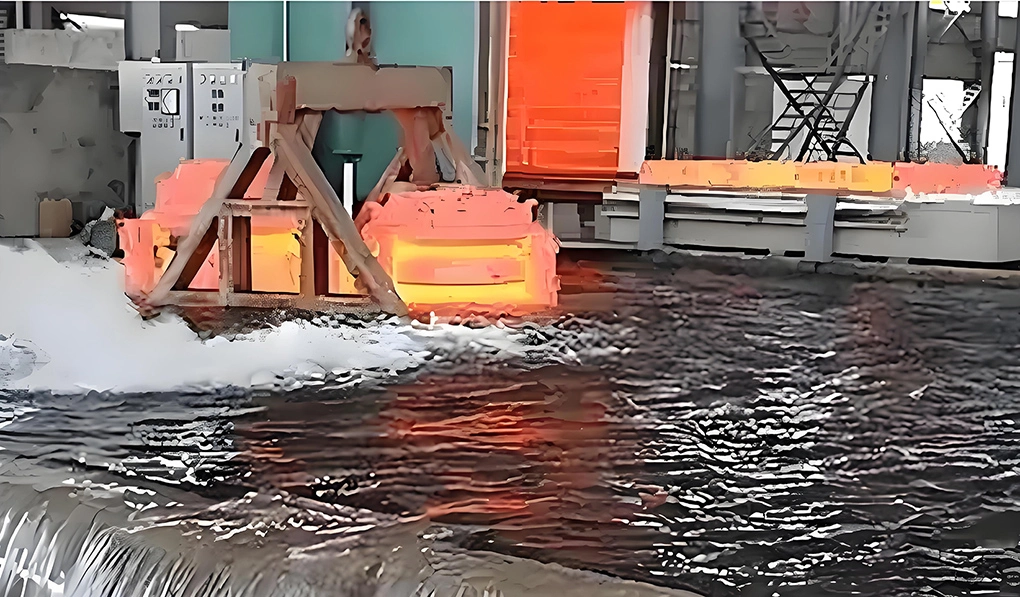

1. Preparation:

The casting or forging is thoroughly cleaned to remove any oils, oxides, or contaminants that may interfere with the nitrogen treatment process. This cleaning can be done using chemical cleaning agents, abrasive blasting, or other methods suitable for the material and component geometry.

2. Nitriding Atmosphere:

The component is placed in a furnace or nitriding chamber, where it is exposed to a nitrogen-rich atmosphere. This atmosphere typically contains ammonia (NH₃), which decomposes at high temperatures to release nitrogen gas.

Nitrogen atoms diffuse into the surface of the part at elevated temperatures, typically between 500°C to 580°C (932°F to 1,076°F), depending on the material composition and the desired case depth.

3. Diffusion Process:

During the nitriding process, nitrogen atoms diffuse into the surface of the component and combine with the metal to form hard nitrides. These nitrides, often iron nitrides (Fe₄N or Fe₇N₆), form a hard surface layer that significantly increases the hardness and wear resistance of the part.

The diffusion depth can be controlled by adjusting the time and temperature of the process. Typically, the depth of the nitrided layer ranges from 0.1 mm to 0.5 mm (0.004 in to 0.02 in), though deeper cases can be achieved for specific applications.

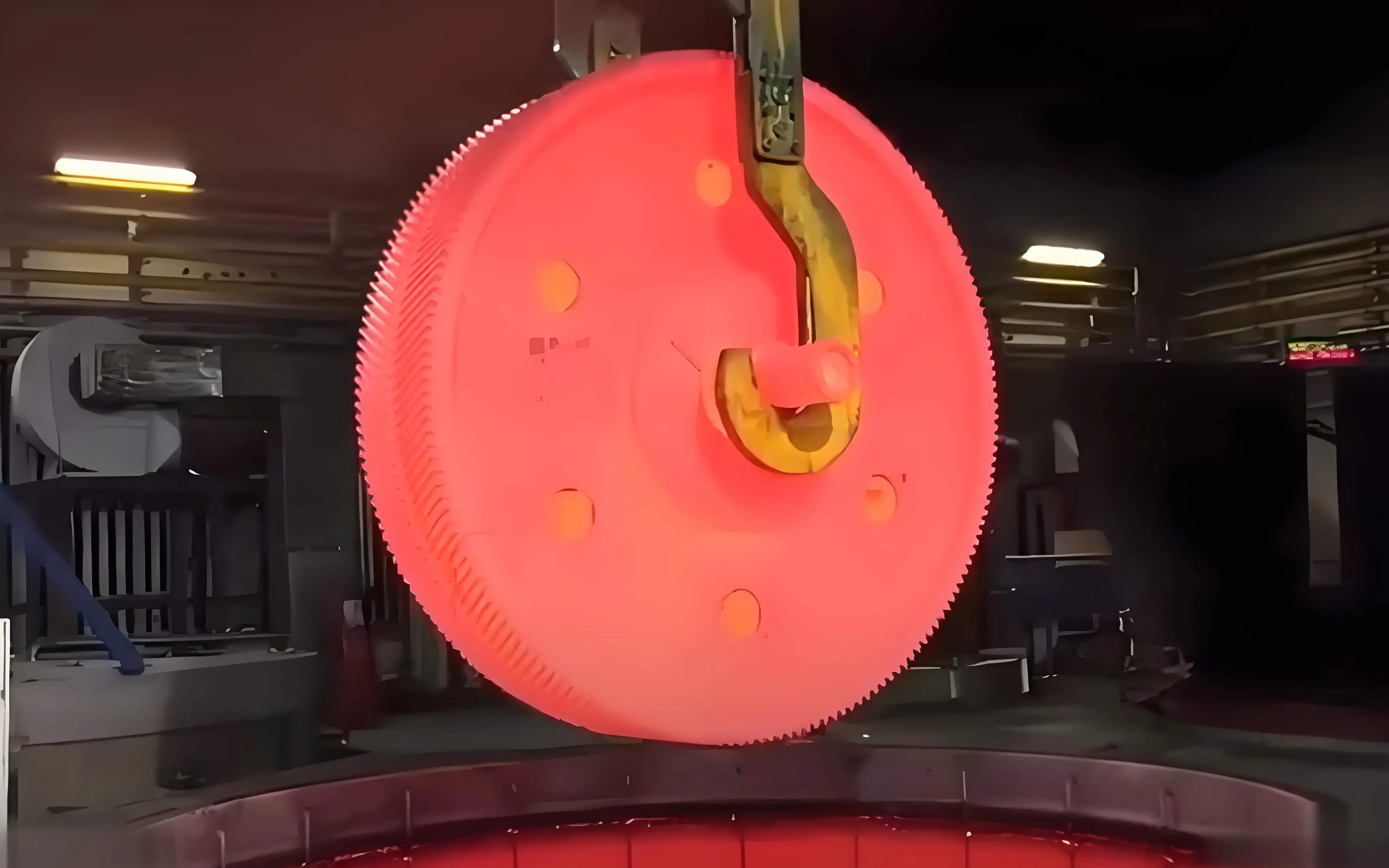

4. Cooling:

After the nitriding process, the part is typically cooled in air or other controlled environments. Unlike other surface hardening methods such as carburizing or induction hardening, nitrogen hardening typically does not require quenching or rapid cooling, as the nitriding process results in a uniform, stable microstructure.

5. Post-Treatment:

Benefits of Nitrogen Hardening for Castings and Forgings

1. Increased Surface Hardness:

2. Superior Wear and Abrasion Resistance:

The nitrided surface layer provides excellent resistance to wear, making nitrogen hardening particularly beneficial for parts exposed to frictional forces, such as gears, shafts, and valve components. The hard nitrides formed during the process act as a barrier against surface degradation.

3. Enhanced Corrosion and Oxidation Resistance:

One of the key advantages of nitrogen hardening is the improved corrosion resistance of the treated parts. The nitrided surface forms a thin, stable oxide layer that protects against oxidation and corrosion, making the process ideal for components that operate in aggressive environments such as aerospace, automotive, marine, and energy sectors.

4. Improved Fatigue Resistance:

The nitrogen hardening process also improves the fatigue resistance of castings and forgings by increasing the surface hardness and promoting a more uniform microstructure. This is essential for components subjected to repeated stress cycles, such as gears, camshafts, and crankshafts.

5. Low Distortion and Minimal Dimensional Changes:

Nitrogen hardening is a relatively low-temperature process compared to other hardening methods, such as carburizing or quenching. This helps to reduce the risk of thermal distortion and dimensional changes, making it particularly suitable for precision parts with tight tolerances.

6. Energy Efficiency:

7. Environmentally Friendly:

Unlike some other surface treatment methods, nitrogen hardening produces minimal emissions and is more environmentally friendly. The process uses nitrogen gas, which is abundant and non-toxic, contributing to a safer and more sustainable manufacturing environment.

Applications of Nitrogen Hardening for Castings and Forgings

Nitrogen hardening is ideal for components in industries where high surface hardness, wear resistance, and corrosion resistance are critical. Key applications include:

· Automotive Industry:

Gears, camshafts, crankshafts, and valve components that are subjected to high wear and mechanical stresses.

Components that require both wear resistance and corrosion resistance, such as fuel system components, suspension parts, and transmission components.

· Energy and Power Generation:

Steam turbine parts, compressor blades, and high-pressure valve components that operate in aggressive thermal and mechanical environments.

Drilling tools, pumps, and other equipment exposed to wear and corrosive media.

· Marine and Oil & Gas:

Marine engine parts, hydraulic components, and other parts that operate in harsh, corrosive environments where both hardness and corrosion resistance are vital.

Subsea equipment and valves that require enhanced wear resistance and corrosion protection.

· Tooling & Dies:

Molds, dies, and stamping tools that require enhanced wear resistance, particularly in high-production environments.

Cold and hot working tools used in metal forming, where high surface hardness and resistance to corrosion are essential.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi