Characteristics of Walkson Open-die forging Products:

1. Large Size and High Strength:

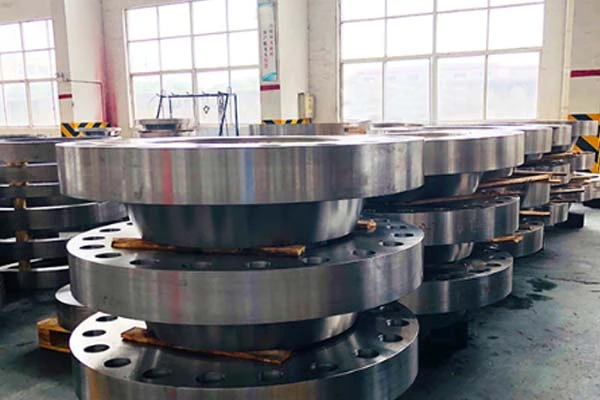

Walkson Open-die forging is ideal for creating large parts such as shafts, blocks, and rings with excellent strength and durability.

2. Simple Shapes:

Products typically have simpler geometries compared to closed-die forgings, though they can be machined into more complex shapes after forging.

3. Customizability:

The process allows for flexibility in size and shape, making it suitable for custom, low-volume, or specialty orders.

4. Superior Material Properties:

Walkson Open-die forging aligns the grain structure of the metal, enhancing strength, toughness, and fatigue resistance.

5. Wide Range of Materials:

It accommodates various materials, including carbon steel, alloy steel, stainless steel, aluminum, titanium, and nickel-based alloys.

Common Walkson Open-die forging Products:

1. Shafts:

Rotors and Drive Shafts: Used in turbines, engines, and heavy machinery.

Marine Propeller Shafts: High-strength components for ships and submarines.

2. Rings:

3. Discs and Hubs:

4. Bars and Blocks:

5. Large Industrial Components:

6. Tooling and Mold Components:

Applications of Walkson Open-die forging Products:

1. Power Generation:

Turbine shafts, generator rotors, and pressure vessel components in thermal, nuclear, and hydroelectric plants.

2. Oil & Gas:

3. Automotive and Heavy Equipment:

Axles, connecting rods, and suspension parts for trucks, trains, and construction machinery.

4. Marine Industry:

5. Mining and Construction:

Advantages of Walkson Open-die forging Products:

1. Improved Mechanical Properties:

2. High Versatility:

3. Cost-Effective for Large Parts:

4. Wide Material Compatibility:

5. Extended Lifespan:

Process Overview of Walkson Open-Die Forging:

1. Heating the Material:

The billet or ingot is heated to a malleable temperature in a furnace.

2. Positioning on the Die:

The workpiece is placed on a flat or simple die, and controlled hammering or pressing is applied.

3. Shaping the Metal:

Skilled operators manipulate the workpiece between hammer blows or press strokes to achieve the desired shape.

4. Cooling and Post-Processing:

After forging, the product is cooled and often undergoes heat treatment or machining to achieve final specifications.

Limitations of Walkson Open-Die Forging:

Less Complex Shapes: Cannot produce intricate or detailed geometries without additional machining.

Requires Skilled Operators: Precision depends on the expertise of the operator and the tools used.

Material Waste: Some excess material may need to be removed during machining.

Summary:

Walkson Open-die forging products are large, durable components with excellent mechanical properties, widely used in industries requiring strength and reliability. This process is ideal for creating custom parts, particularly for heavy-duty applications in heavy machinery, power generation, oil & gas, and marine industries.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi