Detailed Applications of Cutting Fabrication

Cutting fabrication is a critical process used in many industries to shape, modify, and prepare raw materials for further processing, assembly, or construction. Cutting can involve various techniques such as mechanical cutting, thermal cutting, and chemical cutting, each with its own set of advantages, limitations, and ideal use cases. This process is crucial in industries ranging from construction and automotive to engineering and manufacturing.

Common Cutting Methods in Fabrication

1. Shearing (Mechanical Cutting)

Description: Shearing involves the use of a mechanical device (shear) to cut metal sheets or plates, typically through a straight line. It is a clean and efficient method for cutting thin to medium-thickness metal.

Applications:

Sheet Metal Cutting: In industries like HVAC, automotive, and shearing is used to cut sheets of steel, aluminum, or other metals into smaller sections.

Structural Components: Shearing is used to prepare structural elements, such as beams or frames, for further processing or assembly.

Packaging Materials: Cutting materials into precise shapes and sizes for packaging or protective structures in the shipping industry.

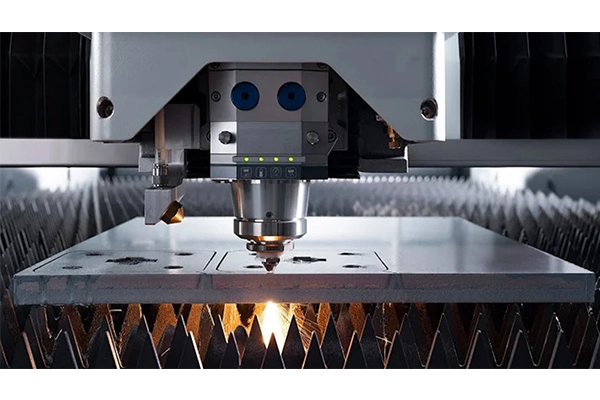

2. Laser Cutting

Description: Laser cutting uses a high-powered laser beam to melt, burn, or vaporize material, achieving precision cuts with high accuracy. The process can be used on a variety of materials including metals, plastics, wood, and ceramics.

Applications:

Precision Manufacturing:Laser cutting is ideal for intricate and high-precision cuts in industries like automotive, and electronics.Precision Manufacturing: Laser cutting is ideal for intricate and high-precision cuts in industries like automotive and electronics. It is commonly used to cut parts such as brackets, housing, and components with complex designs.

Custom Signage: For signage or artwork, laser cutting is often used to create detailed and complex shapes in metal, acrylic, and wood.

Tooling: Laser cutting is used to create tooling parts such as molds, dies, and templates, especially in industries requiring tight tolerances.

Medical Devices: The medical industry uses laser cutting to produce high-precision parts like surgical instruments, medical devices, and implants, ensuring minimal deviation from design specifications.

3. Plasma Cutting

Description: Plasma cutting utilizes a jet of ionized gas (plasma) to cut through electrically conductive materials, such as steel, stainless steel, aluminum, and brass. It is a fast and efficient cutting process, especially for thicker materials.

Applications:

Heavy Steel Cutting: Plasma cutting is commonly used in industries that require cutting through thick steel or other metals, such as construction, shipbuilding, and heavy manufacturing.

Pipe Cutting: In industries like oil and gas, plasma cutting is used for cutting pipes and tubular structures. It provides fast, clean cuts with minimal heat distortion.

Automotive: Plasma cutting is used for cutting sheet metal and structural components in automotive industries, especially for parts requiring fast turnaround and moderate precision.

4. Waterjet Cutting

Description: Waterjet cutting involves the use of a high-pressure stream of water, often mixed with an abrasive material like garnet, to cut through materials. It can cut a variety of materials including metals, glass, stone, ceramics, and composites.

Applications:

Stone and Tile Cutting: Waterjet cutting is often used in the stone, marble, and tile industries to create intricate shapes and designs. The cold-cutting nature of waterjet cutting prevents the material from cracking or distorting.

Composites and Laminates: Waterjet cutting is ideal for cutting composite materials used in industries like automotive, and construction, as it does not affect the integrity of layered structures.

Metal Cutting: While less common for cutting thick metals than plasma or laser, waterjet cutting is used for precision cuts in metals, especially when heat-affected zones are a concern.

5. Oxy-Fuel Cutting (Oxy-Acetylene Cutting)

Description: Oxy-fuel cutting uses a combination of oxygen and a fuel gas (typically acetylene) to heat the material to its ignition point and then blow the molten material away. It is mostly used for cutting ferrous metals (iron and steel).

Applications:

Heavy Plate Cutting: This method is commonly used for cutting thicker steel plates, especially in the construction and shipbuilding industries.

Scrap Metal Cutting: Oxy-fuel cutting is often employed in the recycling industry to cut scrap metal into smaller, manageable pieces for further processing.

Pipeline Cutting: Oxy-fuel is often used for cutting large-diameter pipes in the oil, gas, and chemical industries, especially for field repairs.

6. Bandsaw Cutting

Description: Bandsaw cutting uses a continuous band of teeth mounted on a set of wheels to cut through materials. This method is often used for cutting wood, metal, and other materials in a straight line or around curves.

Applications:

Woodworking: In woodworking, bandsaws are used for cutting large sheets of wood or making intricate curves for furniture or cabinetry.

Metal Cutting: Bandsaws are used to cut metal bars, pipes, and other structural materials, especially for applications requiring straight cuts and medium precision.

Pipe and Tube Cutting: Bandsaws are also used in industries like plumbing, oil, and gas for cutting pipes and tubes into specific lengths.

7. Wire EDM (Electrical Discharge Machining)

Description: Wire EDM uses a thin wire as an electrode to cut through metal by applying electrical discharges. It is an extremely precise method, often used for complex shapes and parts with fine details.

Applications:

Tool and Die Making: Wire EDM is extensively used in tool and die manufacturing, where high precision and tight tolerances are required. This method is ideal for creating mold cavities, dies, and other specialized parts.

Medical Implants: Wire EDM is used in the medical industry for making highly detailed parts, such as implants and surgical instruments, where precision is crucial.

8. Laser Ablation

Description: Laser ablation involves using a focused laser beam to remove material from the surface by vaporization or melting. This method is highly controlled and can be used for both cutting and surface preparation.

Applications:

Microfabrication: Laser ablation is commonly used for cutting and shaping microscopic components in electronics, optics, and precision engineering.

Printed Circuit Boards (PCBs): Laser cutting is used in electronics manufacturing to create precise cuts in PCB materials, allowing for high-density circuit designs.

9. Slitting

Description: Slitting involves using rotary blades to cut continuous coils or sheets of material into narrower strips. It is often used in the steel, aluminum, and plastic industries.

Applications:

Roll Forming: In roll forming, slitting is used to cut long strips of metal into shorter lengths or to separate different widths for manufacturing processes.

Packaging Materials: Slitting is used in the packaging industry to cut materials like paper, plastic, and aluminum foil into strips or sheets for further processing or packaging.

Detailed Applications in Key Industries

1. Construction and Structural Fabrication

Steel Plate Cutting: In construction, cutting methods like laser and plasma cutting are used for shaping steel plates, beams, and columns for structural projects such as buildings, bridges, and other infrastructure.

Pre-Engineered Buildings: For pre-engineered metal building systems (PEBs), cutting is used to fabricate roof panels, wall panels, and structural supports with precision.

2. Automotive Manufacturing

Body Panel Cutting: Laser and mechanical cutting methods are employed to create body panels, chassis components, and interior parts with high precision. Cutting processes are essential for parts that require both dimensional accuracy and high-speed production.

Exhaust Systems: Plasma and laser cutting are used to shape and form the components of automotive exhaust systems, including pipes, mufflers, and catalytic converters.

3. Metalworking and Fabrication

Custom Metal Parts: In general metalworking and fabrication, cutting methods like waterjet, laser, and plasma cutting are employed to produce custom parts for everything from machinery to home goods. These cuts are often followed by processes such as welding, bending, or forming.

Sheet Metal Processing: Shearing, laser cutting, and plasma cutting are commonly used in the fabrication of sheet metal components used in HVAC systems, signage, and automotive parts.

4. Shipbuilding

Hull and Deck Cutting: Plasma and oxy-fuel cutting are typically used in shipbuilding to cut large sections of steel plate used in the construction of ship hulls, decks, and other structures.

Pipe Cutting: In shipbuilding, cutting methods are used for cutting pipes and tubing for the ship’s plumbing, fuel systems, and ventilation systems.

5. Energy and Power Generation

Turbine and Generator Parts: Cutting is used in the manufacturing of turbine blades, generator housings, and other components in the power generation industry. Laser and wire EDM cutting are often employed to achieve the precision required for these critical parts.

Piping for Oil and Gas: Plasma cutting is frequently used to cut piping for oil and gas industries, including the extraction, refining, and transportation of energy resources.

Material we can do but not limited:

AISI 4130, AISI 4140, AISI 4330, AISI 4340, AISI 8620, AISI 8630, AISI 9310, Nitralloy 135

AISI 1010, AISI 1018, AISI 1020, AISI 1026

Stainless Steel 300 Series

Grade 302, Grade 304, Grade 304-l, Grade 309, Grade 310, Grade 316, Grade 316-L, Grade 317, Grade 321, Grade 330

Stainless Steel 400 Series

Grade 403, Grade 405, Grade 410, Grade 414, Grade 416, Grade 418, Grade 422, Grade 431, Grade 440-A, Grade 440-C

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi