Applications of CNC Planning and Shaping for Castings and Forgings

1. Surface Planing:

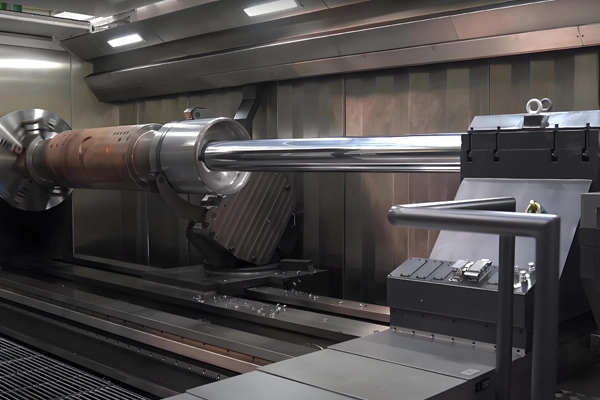

Large Surface Flattening: Planing is ideal for creating smooth, flat surfaces on large and heavy castings and forgings (e.g., machine beds, plates, and frames).

High-Precision Flatness: Critical for parts where high flatness tolerance is essential for assembly or further machining operations.

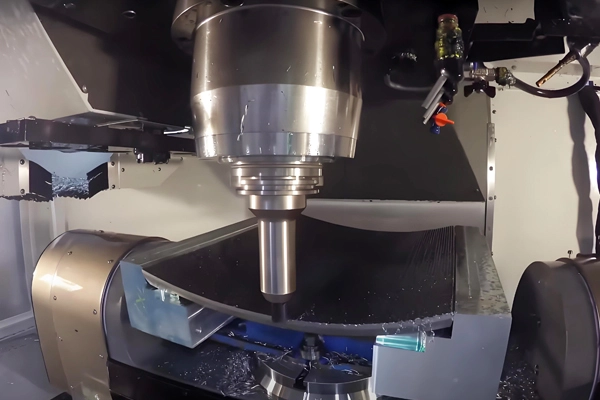

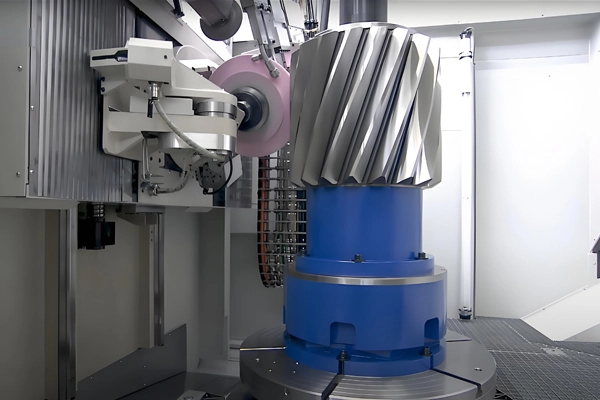

2. Profile Shaping:

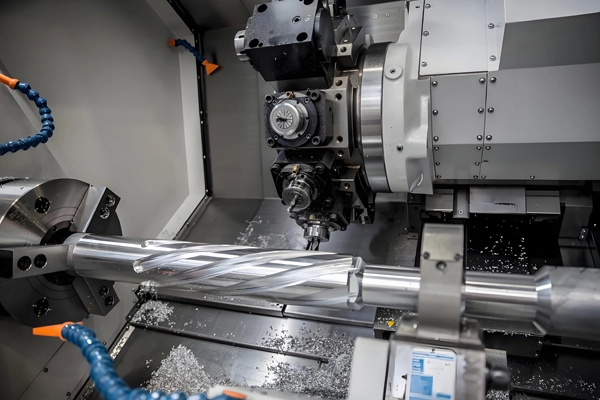

Complex Contours and Geometries: Shaping creates irregular, concave, or convex profiles and features on castings and forgings.

Keyway and Slot Cutting: Produces grooves, keyways, or slots for assembly and functional purposes.

3. Dimensional Adjustments:

4. Finishing of Large Castings and Forgings:

5. Squaring:

Recommended Machines for CNC Planning and Shaping

1. CNC Planers:

Fermat CNC Planers: These machines are known for their stability and precision, ideal for large castings and forgings.

Schneider CNC Planers: Offers high-performance machining for large and heavy-duty components. Schneider planers are commonly used in the heavy machinery industry.

Mazak CNC Planers: Mazak offers flexible solutions with advanced features, enabling planing of complex surfaces and profiles.

2. CNC Shapers:

Shibaura CNC Shapers: Known for high precision in shaping large castings and forgings, especially for aerospace and automotive industries.

Bhurji CNC Shaping Machines: High-performance shapers for automotive and manufacturing components where quality and precision are paramount.

Doosan CNC Shapers: Doosan's CNC shaping machines are designed for efficiency and precision, particularly for industries like energy and defense.

3. Bridge-Type CNC Planing Machines:

Okuma Bridge Planers: These machines are great for working with large and heavy workpieces, with high accuracy and stability.

Keller CNC Planing Machines: Offers reliable solutions for rough and fine planing operations on heavy parts, widely used in industries like steel and foundries.

4. Universal CNC Machines with Planing and Shaping Capabilities:

DMG Mori CNC Milling/Planing Combination Machines: These machines allow for both planing and milling capabilities, providing flexibility for various types of machining operations on castings and forgings.

Haas CNC Universal Machines: Suitable for both planing and shaping tasks, these machines offer high versatility with large work envelope capabilities.

Dimensional Inspection Measures

1. Coordinate Measuring Machines (CMM):

2. Surface Roughness Testers:

3. Straightness and Flatness Gauges:

4. Feeler Gauges and Dial Indicators:

5. Optical Comparators:

6. Laser Scanning Systems:

Inspection Reports

1. First Article Inspection (FAI):

2. Geometric Dimensioning and Tolerancing (GD&T) Reports:

Includes a detailed report of the dimensional and geometric tolerances for flatness, parallelism, perpendicularity, and profile.

3. Surface Finish Reports:

4. Dimensional Inspection Reports:

Provides detailed measurements of all critical features, including flatness, dimensions, and alignment.

5. Material Test Reports (MTR):

6. Runout and Parallelism Reports:

Quality Control Measures

1. Pre-Machining Inspection:

Evaluate raw castings or forgings for defects like cracks, porosity, or alignment issues, as these can affect the planing or shaping operation.

2. Tool Condition Monitoring:

3. In-Process Monitoring:

4. Post-Machining Inspection:

Verifies all critical dimensions after machining, ensuring flatness, straightness, and profile meet design specifications.

5. Non-Destructive Testing (NDT):

6. Traceability:

7. Compliance with Industry Standards:

Ensures adherence to international standards like ISO 9001, AS9100, or IATF 16949, ensuring that the products meet quality and performance standards required by the industry.

Advantages of CNC Planing and Shaping for Castings and Forgings

1. High Precision:

Ensures flatness, parallelism, and smoothness within tight tolerances, especially on large, heavy parts.

2. Cost-Effective for Large Parts:

3. Versatility:

4. Reduced Lead Time:

5. Consistency and Repeatability:

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi