Applications of CNC Turning for Castings and Forgings

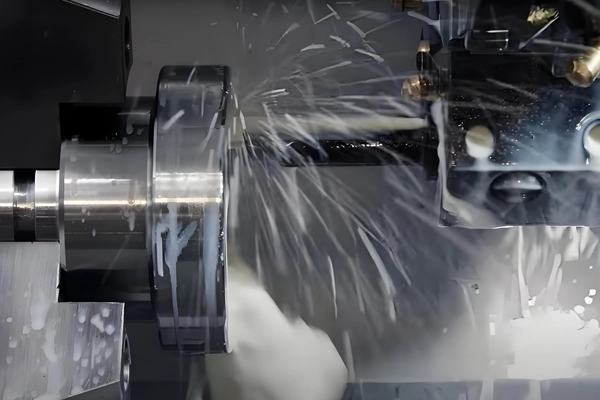

1. Precision Machining:

Creates cylindrical, conical, and spherical components.

Commonly used for shafts, rings, sleeves, flanges, and couplings.

2. Threading and Grooving:

3. Facing and Contouring:

4. Boring and Reaming:

5. Chamfering and Deburring:

6. High-Volume Production:

Machines Used for CNC Turning

1. CNC Turning Centers:

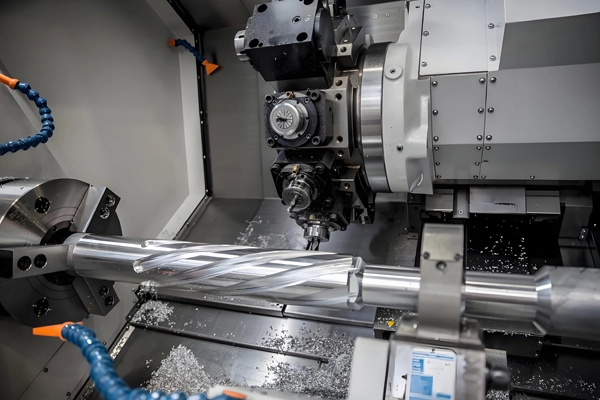

2. Multi-Axis CNC Turning Machines:

3. Vertical Turning Lathes (VTL):

4. CNC Mill-Turn Centers:

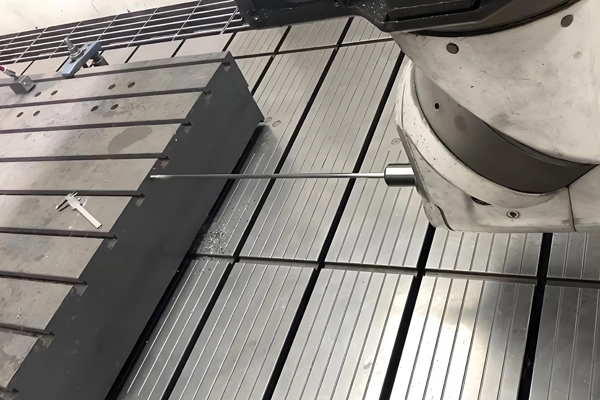

Dimensional Inspection Measures

1. Manual Inspection Tools:

2. Coordinate Measuring Machines (CMM):

3. Profile Projectors:

4. Surface Roughness Testers:

5. Runout and Concentricity Gauges:

6. Optical and Laser Scanners:

Inspection Reports

1. First Article Inspection (FAI):

2. Geometric Dimensioning and Tolerancing (GD&T) Reports:

3. Thread Inspection Reports:

4. Material Test Reports (MTR):

5. Surface Finish Reports:

6. Runout and Alignment Reports:

Quality Control Measures

1. Pre-Machining Inspection:

2. In-Process Monitoring:

3. Post-Machining Inspection:

4. Tool Wear Monitoring:

5. Non-Destructive Testing (NDT):

6. Compliance with Standards:

7. Traceability:

Key Benefits of CNC Turning for Castings and Forgings

1. High Precision: Achieves tight tolerances essential for industrial applications.

2. Enhanced Efficiency: Reduces lead times with automated processes.

3. Repeatability: Ensures consistency across high-volume production runs.

4. Cost-Effectiveness: Minimizes material waste and rework costs.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi