WALKSON Steel Casting Advantage

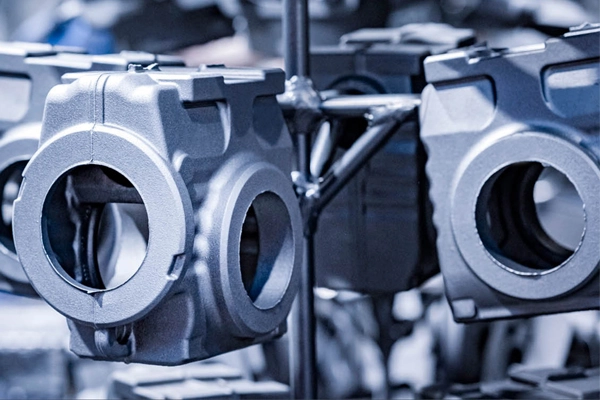

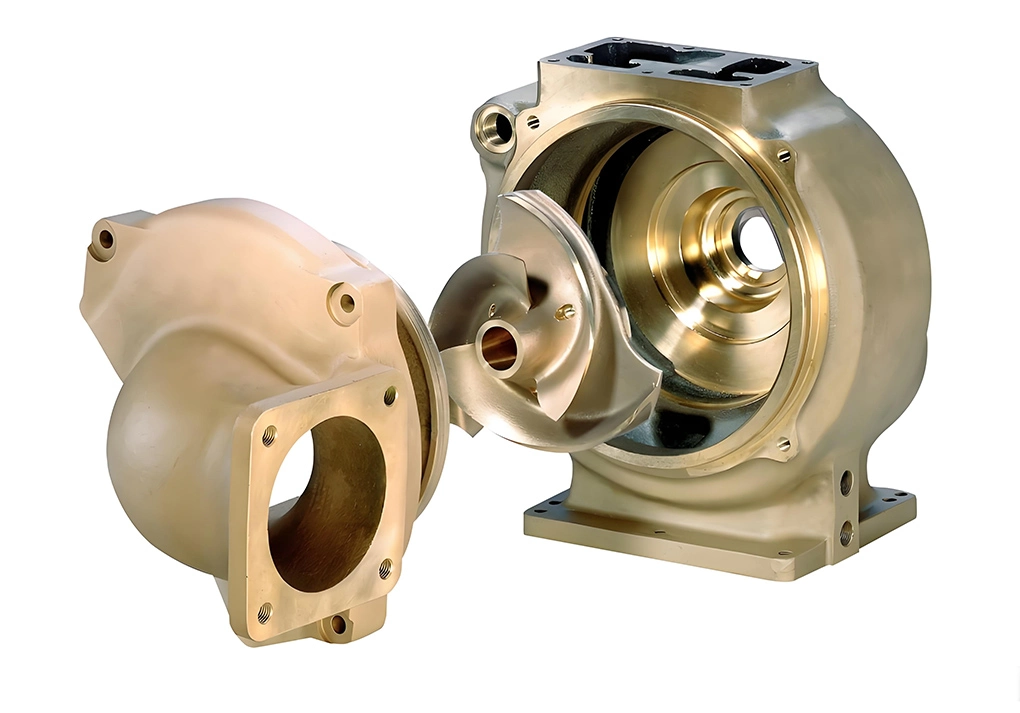

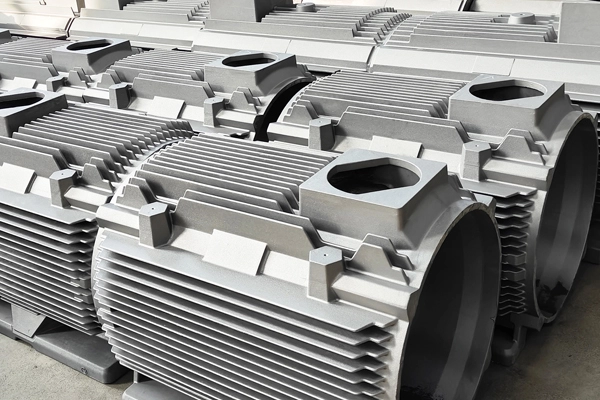

WALKSON steel casting foundry had been working on steel casting for decades, we manufacture low alloy steel casting, stainless steel casting, etc..

Firstly, WALKSON have advantaged equipment for sand mould casting process. We have 2 sets EAF(Electric Arc Furnace) and one set AOD(Argon Oxygen Decarburization Furnace) for our metal refining, which can produce higher purity of molten steel, secondary the EAF(electric arc furnace uses scrap steel as the main raw material, so the electric arc furnace steelmaking can reuse the alloy elements in the scrap steel, this 2 area will absolutely ensure WALKSON steel casting have high-level quality castings and reduce the sand casting cost to buy high-quality scrap metal which benefits our customers on the cost but the quality is on the top level of our casting. With the electric arc furnace and argon oxygen decarburization furnace, we are on the top level in china's sand casting foundry.

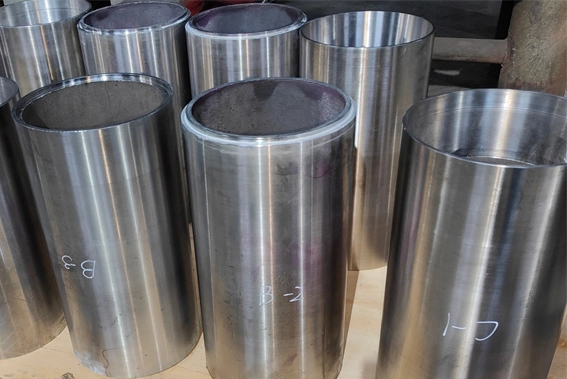

Secondary our steel casting Heat treatment furnace and quench tank (with the stirring system) which can ensure our steel casting manufacturing process can reach high stand mechanical property, include Charpy test, tensile test, and hardness test, with this equipment, our sand casting factory can produce high-level steel castings and improve the casting life a lot.

Thirdly, we are certificated with ISO9001, ISO14000, ISO18000, and invest a lot of environmental protection equipment to our sand casting foundry which approved by the government which ensures we will never stop manufacturer all the year, banish our customer's worries that many sand casting foundry will shut down a few months in a year which will keep our delivery time on time.

Lastly, our people are professional in technical and quality control, and are familiar with types of sand casting process like resin bonded sand casting. We control every process, from molding, melting, pouring, knockout, HT(heat treatment, include annealing, quench, temper), UT, MT, Final machining, we always have our QC people onsite witness and technical support ensure 100% good quality steel castings are manufactured and delivered to our customer.

With the advantaged equipment, different sand casting types, top-level casting quality and 98% delivery on time, WALKSON will be your first choice.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi