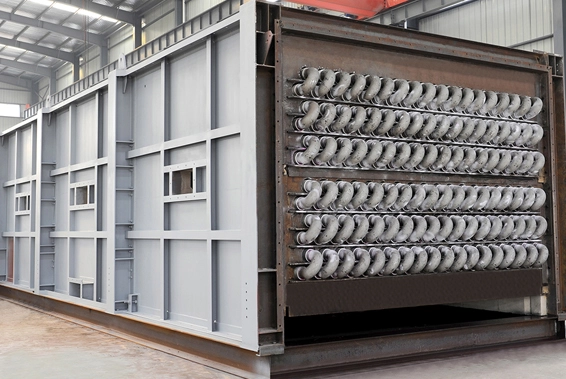

Product Application: Custom-Cast Convection Modules in Continuous Reforming Heaters

Custom-cast convection modules are integral to continuous reforming heaters, which preheat hydrocarbon feedstocks for catalytic reforming processes that produce high-octane gasoline and aromatics. WALKSON’s convection modules are tailored for the following applications:

· Oil Refining Industry:

Catalytic Reforming Units: Modules facilitate heat transfer in convection sections, preheating feedstocks at temperatures up to 650°C while resisting corrosive gases and thermal cycling.

Platforming Processes: Support the production of reformate for gasoline blending, ensuring consistent performance in high-pressure environments.

· Petrochemical Industry:

Aromatics Production: Enable efficient heating of feedstocks for benzene, toluene, and xylene production, withstanding carburizing and oxidizing conditions.

· Additional Applications:

Naphtha reforming, hydrogen production, and other high-temperature heater systems requiring reliable convection modules for optimal heat recovery.

These modules are engineered to operate under demanding conditions, including temperatures up to 700°C, pressures up to 50 bar, and exposure to corrosive and erosive environments, delivering exceptional durability in continuous reforming heaters.

Functions of WALKSON Custom-Cast Convection Modules

WALKSON’s custom-cast convection modules provide essential functionality in continuous reforming heaters:

· Enhanced Heat Recovery: Precision-designed modules maximize heat transfer from flue gases to feedstocks, improving energy efficiency and reducing fuel consumption.

· Thermal Durability: Constructed from high alloy and nickel-based materials (e.g., Inconel 601, Hastelloy C22, HP alloys), modules withstand prolonged exposure to high temperatures.

· Corrosion and Oxidation Resistance: Nickel-based alloys protect against carburization, sulfidation, and oxidation, ensuring long-term performance in aggressive environments.

· Structural Robustness: The centrifugal casting process creates a dense, uniform microstructure, enhancing creep resistance and mechanical strength.

· Tailored Designs: Available in custom configurations, including tube diameters, fin arrangements, and module layouts, to meet specific heater requirements.

Manufacturing Process: Precision and Standards Compliance

WALKSON’s custom-cast convection modules are produced using advanced technology and rigorous adherence to international standards, ensuring superior quality. Below is a comprehensive overview of the production stages:

1. Material Selection and Verification

· Standards: ASTM A351, ASTM A494, DIN EN 10295, and client-specific requirements.

· Materials: High alloy steels (e.g., HH, HK) and nickel-based alloys (e.g., Inconel 718, Hastelloy B2).

· Process: Materials are sourced from certified suppliers and analyzed for chemical composition per ASTM E350 to confirm alloy purity and compliance.

· Equipment: High-precision optical emission spectrometers for material analysis.

2. Alloying and Melting

· Standards: ISO 9001 and ASME Section IX for consistent melt quality.

· Process: Alloys are melted in electric arc or induction furnaces, refined to remove impurities, and conditioned for uniform composition.

· Equipment: High-efficiency electric arc furnaces (EAF) and vacuum induction melting systems.

· Quality Control: Melt samples are tested to meet ASTM E350 standards.

3. Centrifugal Casting

· Standards: ASTM A781, EN 12680, and API 934 for casting integrity.

· Process: Molten alloy is poured into a rotating mold designed for the module’s complex geometry, including tubes and fins. Centrifugal force compacts the material, forming a dense, defect-free structure with a refined microstructure.

· Equipment: Automated horizontal centrifugal casting machines with precise control over rotation and temperature.

· Benefits: Produces modules with superior strength, thermal stability, and accurate geometry.

4. Thermal Processing

· Standards: ASTM A703, ASME Section VIII, and client-defined protocols.

· Process: Modules are heat-treated through annealing, quenching, or tempering to enhance creep resistance, toughness, and corrosion properties.

· Equipment: Programmable heat treatment furnaces with real-time monitoring.

· Quality Control: Thermal cycles are tracked to comply with ISO 9001 standards.

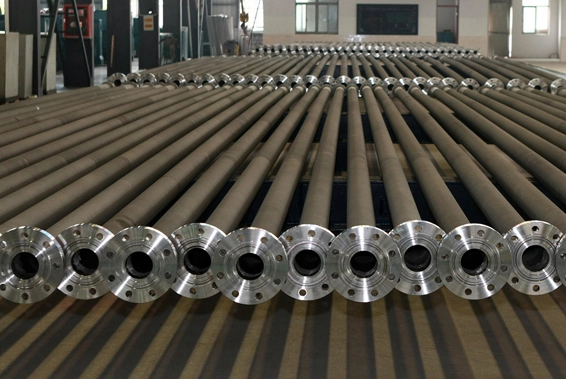

5. Machining and Assembly

· Standards: ISO 2768 for dimensional accuracy, ASME B16.9 for fittings, and ASTM A999 for surface quality.

· Process: Modules are machined to precise specifications using CNC equipment, with fins and tubes assembled into complete units. Surface finishes are optimized for performance, and fittings are added as needed.

· Equipment: CNC milling machines, lathes, and welding systems.

· Quality Control: Dimensional checks are performed using coordinate measuring machines (CMM).

6. Quality Control and Testing

WALKSON implements stringent testing protocols to ensure module reliability, offering full transparency to clients and third-party inspectors (e.g., SGS, Bureau Veritas). Clients can witness all tests as outlined in our Inspection and Test Plan (ITP).

Non-Destructive Testing (NDT)

· 100% X-Ray Inspection:

Standard: ASTM E142, EN 12681.

Purpose: Identifies internal flaws like voids, cracks, or inclusions in tubes and fins.

Equipment: High-resolution digital X-ray systems.

Process: Full scanning of modules with detailed reporting of results.

· 100% Eddy Current Testing:

Standard: ASTM E309, EN 1971.

Purpose: Detects surface and near-surface defects, such as micro-cracks or pitting.

Equipment: Multi-frequency eddy current testing units.

Process: Comprehensive surface testing for defect-free assurance.

· Ultrasonic Testing (UT):

Standard: ASTM A388, EN 12680.

Purpose: Verifies wall thickness consistency and internal integrity of tubes and fins.

Equipment: Automated ultrasonic scanners with high-frequency probes.

Process: Full scanning to ensure structural compliance.

Destructive Testing (where applicable)

· Tensile Strength Testing:

Standard: ASTM E21.

Purpose: Evaluates strength and ductility under stress.

Equipment: High-capacity tensile testing machines.

· Creep Resistance Testing:

Standard: ASTM E292.

Purpose: Assesses performance under sustained high-temperature loads.

Equipment: Specialized creep testing ovens.

· Microstructure Analysis:

Standard: ASTM E1351.

Purpose: Verifies grain structure and material uniformity.

Equipment: Metallographic microscopes with digital imaging.

Hydraulic Pressure Testing

· Standard: ASME B31.3, API 934, and client requirements.

· Purpose: Confirms the module’s ability to withstand design pressures (e.g., up to 50 bar for reforming heaters).

· Process: Modules are pressurized with water to 1.5 times the design pressure and held to check for leaks or deformation.

· Equipment: Automated hydraulic testing systems with digital pressure gauges.

· Client Witnessing: Clients or third-party inspectors are invited to observe testing for compliance verification.

Documentation

· Inspection and Test Plan (ITP): Comprehensive ITP details all inspection and testing phases, available for client review.

· Welding Procedure Specification (WPS) and Procedure Qualification Record (PQR): Pre-qualified per ASME Section IX for welded components, provided upon request.

· Material Test Reports (MTR): Issued per EN 10204 Type 3.1 or 3.2, documenting chemical, mechanical, and test data.

· Inspection Reports: Detailed records of NDT, pressure tests, and dimensional checks, certified by third-party inspectors if required.

· Reference List: Available to showcase WALKSON’s successful delivery of convection modules to global refining and petrochemical projects.

Advantages of Choosing WALKSON

Selecting WALKSON for custom-cast convection modules offers distinct advantages, positioning us as the top choice for continuous reforming heater components:

1. Unmatched Quality: Our modules meet rigorous international standards, supported by 100% NDT and thorough quality assurance.

2. Custom Engineering: Tailored module designs, alloy formulations, and fin configurations to meet specific heater requirements.

3. Global Credibility: Trusted by leading refineries and petrochemical plants worldwide, with a reference list highlighting successful project deliveries.

4. Full Transparency: Third-party inspections (e.g., SGS, BV) and client-witnessed testing ensure trust and accountability.

5. Cutting-Edge Technology: Advanced centrifugal casting, CNC machining, and NDT systems deliver precision and durability.

6. Expert Support: Our skilled engineers provide comprehensive guidance, from design consultation to system integration.

7. Prompt Delivery: Optimized production and logistics ensure fast turnaround without sacrificing quality.

8. Eco-Friendly Practices: Sustainable manufacturing minimizes environmental impact, aligning with global green standards.

9. Cost Efficiency: Durable modules reduce maintenance and downtime, lowering long-term operational costs.

Consult with WALKSON Today

Enhance your continuous reforming heaters with WALKSON’s high alloy and nickel-based custom-cast convection modules. Built for efficiency, corrosion resistance, and compliance with stringent industry standards, our modules deliver outstanding performance in the most demanding refining environments.

Contact WALKSON now to discuss your project requirements, request a quote, or schedule a consultation with our technical specialists. Visit www.walkson.com or email info@walkson.com (mailto:info@walkson.com). Partner with WALKSON for high-quality centrifugal casting solutions.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi