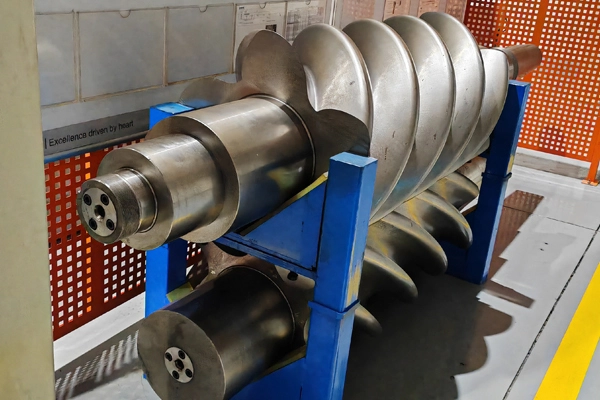

Producing open-die forged screw rotors with large diameters (e.g., 580mm) involves a series of complex and high-precision processes, each of which incurs specific costs. The cost breakdown can vary depending on the material used, production volume, tolerances, and the machining complexity of the rotor. Below is a general cost breakdown for producing large-diameter screw rotors using open-die forging, which is a custom and often low-to-medium volume manufacturing process:

1. Material Costs

Material Type: The cost of the material depends on the alloy chosen. High-strength steels such as 42CrMo4, 17CrNiMo6, or AISI 4140 are commonly used for screw rotors.

Material Cost per kg: The cost of steel alloys typically ranges from $3–$7 per kg, depending on alloy grade and market conditions.

Weight of Rotor: For large-diameter screw rotors (e.g., 580mm), the weight can range between 100kg–300kg or more, depending on the thickness and complexity of the rotor.

Cost Estimate:

2. Pre-Forge Preparation

Billet/Bar Inspection and Cutting:

Billet cost: Additional costs are associated with cutting the billet to size and inspecting it for defects before forging.

Cost per unit of billet: This typically ranges from $50–$200 depending on the size and type of billet.

Cutting and handling: Labor and machine time for cutting and preparation.

Cost Estimate:

Billet cost: $200–$500 depending on the size.

Preparation cost: Additional $100–$200 for cutting, cleaning, and preparation.

3. Open-Die Forging

Equipment Costs:

Forging Press/Hammer: The cost of using hydraulic presses or mechanical hammers for open-die forging. This typically involves large, expensive machinery, often requiring custom setups.

Press usage rate: A typical forging press might cost between $500–$2,000 per hour to operate, including energy consumption, maintenance, and amortization of equipment costs.

Labor Costs:

Forge operator labor cost: Skilled operators are needed for each stage of the forging process. This could cost $50–$100 per hour depending on location and experience.

Total forging time: Depending on complexity, forging a large screw rotor could take anywhere from 6 to 20 hours.

Additional Costs:

Die Wear and Maintenance: Open-die forging can cause wear on the dies, especially for large parts. Die costs and replacement can range from $500–$3,000 for custom dies, depending on the complexity and material used.

Energy Costs: High energy consumption for heating and forging can add significant costs, ranging from $200–$1,000 per forging operation.

Cost Estimate:

Forge Equipment and Labor: $2,000–$10,000 per rotor

Die costs and energy: $1,000–$3,000

4. Heat Treatment

Furnace Costs:

Heat treatment equipment (e.g., induction or batch furnaces) can be expensive, especially for large parts. The cost per cycle might range from $500–$2,000, depending on the size and complexity of the part.

Heating and cooling times: Heat treatment of large-diameter parts takes longer due to the mass and requires controlled cooling, which can increase energy costs.

Labor and Supervision Costs:

Cost Estimate:

5. Machining and Surface Finishing

CNC Machining:

CNC Turning/Milling: The process of machining large screw rotors is labor- and machine-intensive. CNC machines charge an hourly rate of $100–$250 per hour depending on machine complexity and part features.

Machining time: Machining time for large rotors can take anywhere from 15 to 50 hours, depending on the size and complexity.

Surface Finishing:

Grinding/Polishing: Fine grinding and polishing for smooth surfaces and critical features can take additional time. This process is generally $50–$100 per hour.

Time for Finishing: 5–15 hours, depending on the quality required and part size.

Cost Estimate:

Machining Cost: $7,500–$15,000 (depending on complexity)

Surface Finishing: $500–$2,000

6. Inspection and Testing

Dimensional Inspection:

CMM (Coordinate Measuring Machine) or Laser Scanning costs are typically $100–$200 per hour.

Time for Inspection: It may take 4–10 hours to thoroughly inspect the rotor, including using 3D scanning or CMM.

NDT (Non-Destructive Testing):

Methods like ultrasonic testing, magnetic particle inspection, and dye penetrant inspection may be employed to detect internal or surface defects.

NDT Cost: For large parts, the cost of NDT services ranges from $500–$2,000 depending on the testing methods used.

Cost Estimate:

7. Balancing and Final Testing

Dynamic Balancing: For screw rotors, dynamic balancing is crucial. The cost of balancing can range from $300–$1,500 per rotor, depending on the machine and complexity.

Functional Testing (if applicable): If the rotor is part of a larger system, it may require performance testing, which can add $500–$3,000 depending on the testing method and equipment.

Cost Estimate:

8. Packaging and Shipping

Packaging: Custom crates, protective materials, and shipping preparation can add significant costs, especially for large and heavy parts.

Shipping: Depending on the destination, international shipping and freight charges can range from $500–$3,000, especially for large, heavy items that require special handling.

Cost Estimate:

Total Estimated Cost Breakdown

Here’s an estimated cost breakdown for producing a single open-die forged screw rotor with a large diameter (e.g., 580mm):

| Cost Element | Estimated Cost Range |

|---|

| Material Costs | $1,000–$20,000 |

| Billet Preparation and Cutting | $200–$500 |

| Forging (Labor, Equipment, Dies) | $2,000–$10,000 |

| Heat Treatment | $1,000–$10,000 |

| Machining and Surface Finishing | $8,000–$27,000 |

| Inspection and Testing (Dimensional & NDT) | $1,000–$3,000 |

| Balancing and Final Testing | $1,000–$4,000 |

| Packaging and Shipping | $500–$3,000 |

Total Estimated Cost for One Rotor:

$14,700 – $87,500 (Depending on complexity, material, labor, and additional features)

Factors That Influence Cost:

Material Choice: Higher-end alloys will increase material costs.

Complexity: The more intricate the rotor’s design (e.g., multiple grooves, special profiles), the higher the machining and inspection costs.

Quantity: Larger production runs reduce the cost per part due to economies of scale, especially for die use, machine setup, and labor.

Tolerances and Surface Quality: Tight tolerances and high-quality finishes demand more time in machining and inspection, increasing costs.

Heat Treatment and Testing Requirements: If specialized heat treatment or rigorous testing (e.g., pressure tests, functional testing) is required, this will add to the cost.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi