Product Application: Centrifugal Cast Pipe Fittings in High-Pressure Systems

Centrifugal cast pipe fittings are critical components in high-pressure systems, connecting pipes and ensuring reliable flow in demanding industrial processes. WALKSON’s fittings are tailored for the following applications:

· Petrochemical Industry:

Hydrogenation Heaters and Reforming Furnaces: Fittings manage high-pressure gas and liquid flows, operating at temperatures up to 800°C and resisting corrosive hydrocarbons.

EDC Cracking Furnaces and Styrene Steam Superheaters: Ensure secure connections in high-pressure piping, withstanding thermal cycling and aggressive chemical environments.

· Oil Refining Industry:

Atmospheric-Vacuum Distillation Units: Support high-pressure crude oil processing, maintaining integrity under elevated pressures up to 100 bar.

Catalytic Cracking Furnaces: Facilitate reliable fluid transfer in high-pressure systems, resisting erosion and carburization.

· Metallurgical Industry:

Cold Rolling Continuous Annealing Lines: Fittings connect radiant tubes and furnace rollers, enduring high-pressure steam and thermal stress.

Rotary Hearth Furnaces: Ensure robust piping connections in screw discharging systems, resisting abrasive and high-temperature conditions.

· Additional Applications:

Pressure vessels, heat exchangers, and towers in large refining projects, where fittings ensure leak-free performance under extreme pressures.

These fittings are engineered to perform in harsh conditions, including temperatures up to 850°C, pressures up to 100 bar, and exposure to corrosive and erosive media, delivering exceptional reliability in high-pressure systems.

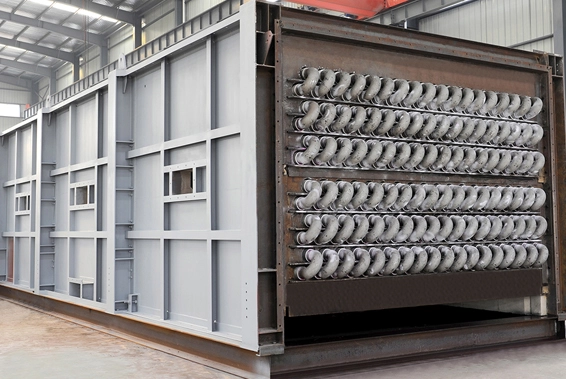

Functions of WALKSON Centrifugal Cast Pipe Fittings

WALKSON’s centrifugal cast pipe fittings provide critical functionality in high-pressure systems:

· Seamless Flow Connectivity: Precision-engineered fittings ensure leak-free connections, maintaining efficient flow of gases or liquids under high pressure.

· Extreme Condition Resilience: Crafted from high alloy and nickel-based materials (e.g., Inconel 600, Hastelloy C276, HP alloys), fittings withstand intense temperatures and pressures.

· Corrosion and Erosion Resistance: Nickel-based alloys protect against sulfidation, carburization, and abrasive wear, ensuring long-term durability in aggressive environments.

· Structural Strength: The centrifugal casting process produces a dense, uniform microstructure, enhancing creep resistance and mechanical stability.

· Customizable Configurations: Available in various shapes (e.g., elbows, tees, reducers), sizes, and connection types to meet specific system requirements.

Manufacturing Process: Excellence and Standards Compliance

WALKSON’s centrifugal cast pipe fittings are produced using state-of-the-art technology and strict adherence to international standards, reflecting our ISO 9001, ISO 14001, ISO 45001, and O/TSY 1002.1 certifications. Below is a detailed overview of the production stages, leveraging our expertise as a high-tech enterprise with 11 state invention patents, including centrifugal casting technology for Inconel 600:

1. Material Procurement and Verification

· Standards: ASTM A351, ASTM A494, DIN EN 10295, and client-specific requirements.

· Materials: High alloy steels (e.g., HH, HK) and nickel-based alloys (e.g., Inconel 625, Hastelloy B2).

· Process: Materials are sourced from certified vendors and analyzed for chemical composition per ASTM E350 to ensure alloy purity and compliance.

· Equipment: High-precision optical emission spectrometers for material analysis.

2. Melting and Alloy Refining

· Standards: ISO 9001 and ASME Section IX for melt quality assurance.

· Process: Alloys are melted in electric arc or induction furnaces, purified to remove contaminants, and treated for uniform composition.

· Equipment: High-capacity electric arc furnaces (EAF) and vacuum induction melting systems.

· Quality Control: Melt samples are tested to meet ASTM E350 standards.

3. Centrifugal Casting

· Standards: ASTM A781, EN 12680, and API 934 for casting integrity.

· Process: Molten alloy is poured into a rotating mold tailored to the fitting’s geometry. Centrifugal force compacts the material, forming a dense, defect-free component with a refined microstructure. This process, refined through our collaboration with the Chinese Academy of Sciences, ensures exceptional quality.

· Equipment: Automated horizontal centrifugal casting machines with precise control over rotation and temperature.

· Benefits: Produces fittings with superior strength, thermal stability, and precise geometry.

4. Heat Treatment

· Standards: ASTM A703, ASME Section VIII, and client-defined protocols.

· Process: Fittings undergo heat treatments like solution annealing or tempering to enhance creep resistance, toughness, and corrosion properties.

· Equipment: Programmable heat treatment furnaces with real-time monitoring.

· Quality Control: Thermal cycles are tracked to comply with ISO 9001 standards.

5. Machining and Finishing

· Standards: ISO 2768 for dimensional accuracy, ASME B16.9 for fittings, and ASTM A999 for surface quality.

· Process: Fittings are machined to precise specifications using CNC equipment, with surface finishes optimized for performance. Threads, flanges, or welded joints are added as needed.

· Equipment: CNC milling machines, lathes, and polishing systems.

· Quality Control: Dimensional checks are performed using coordinate measuring machines (CMM).

6. Quality Control and Testing

WALKSON’s rigorous testing protocols, backed by our complete quality management system and partnerships with research universities, ensure fitting reliability. We offer full transparency to clients and third-party inspectors (e.g., SGS, Bureau Veritas), with clients invited to witness all tests as outlined in our Inspection and Test Plan (ITP).

Non-Destructive Testing (NDT)

· 100% X-Ray Inspection:

Standard: ASTM E142, EN 12681.

Purpose: Detects internal flaws like voids, cracks, or inclusions.

Equipment: High-resolution digital X-ray systems.

Process: Full scanning of fittings with detailed reporting of results.

· 100% Eddy Current Testing:

Standard: ASTM E309, EN 1971.

Purpose: Identifies surface and near-surface defects, such as micro-cracks or pitting.

Equipment: Multi-frequency eddy current testing units.

Process: Comprehensive surface testing for defect-free assurance.

· Ultrasonic Testing (UT):

Standard: ASTM A388, EN 12680.

Purpose: Verifies wall thickness consistency and internal integrity.

Equipment: Automated ultrasonic scanners with high-frequency probes.

Process: Full scanning to ensure structural compliance.

Destructive Testing (where applicable)

· Tensile Strength Testing:

Standard: ASTM E21.

Purpose: Evaluates strength and ductility under stress.

Equipment: High-capacity tensile testing machines.

· Creep Resistance Testing:

Standard: ASTM E292.

Purpose: Assesses performance under sustained high-temperature loads.

Equipment: Specialized creep testing ovens.

· Microstructure Analysis:

Standard: ASTM E1351.

Purpose: Verifies grain structure and material uniformity.

Equipment: Metallographic microscopes with digital imaging.

Hydraulic Pressure Testing

· Standard: ASME B31.3, API 934, and client requirements.

· Purpose: Confirms the fitting’s ability to withstand design pressures (e.g., up to 100 bar for high-pressure systems).

· Process: Fittings are pressurized with water to 1.5 times the design pressure and held to check for leaks or deformation.

· Equipment: Automated hydraulic testing systems with digital pressure gauges.

· Client Witnessing: Clients or third-party inspectors are invited to observe testing for compliance verification.

Documentation

· Inspection and Test Plan (ITP): Detailed ITP outlines all inspection and testing phases, available for client review.

· Welding Procedure Specification (WPS) and Procedure Qualification Record (PQR): Pre-qualified per ASME Section IX for welded components, provided upon request.

· Material Test Reports (MTR): Issued per EN 10204 Type 3.1 or 3.2, documenting chemical, mechanical, and test data.

· Inspection Reports: Comprehensive records of NDT, pressure tests, and dimensional checks, certified by third-party inspectors if required.

· Reference List: Available to showcase WALKSON’s successful delivery of pipe fittings to global refining and metallurgical projects.

Advantages of Choosing WALKSON

Choosing WALKSON for centrifugal cast pipe fittings offers distinct advantages, positioning us as the preferred supplier for high-pressure system components:

1. Uncompromising Quality: Our fittings meet rigorous international standards, backed by 100% NDT and a robust quality management system certified to ISO 9001, ISO 14001, and ISO 45001.

2. Customized Engineering: Tailored fitting designs, alloy formulations, and configurations to meet specific high-pressure system needs, leveraging our 11 state invention patents.

3. Global Trust: Trusted by industry leaders like SINOPEC, CNPC, and CNOOC, with a reference list highlighting successful deliveries to large refining and steel projects worldwide.

4. Transparent Processes: Third-party inspections (e.g., SGS, BV) and client-witnessed testing ensure trust and accountability.

5. Innovative Technology: Advanced centrifugal casting, CNC machining, and NDT systems, developed in collaboration with the Chinese Academy of Sciences, deliver precision and durability.

6. Expert Support: Our expert team, backed by our Academician Workstation, provides end-to-end guidance from design to installation.

7. Timely Delivery: Streamlined production and logistics ensure fast turnaround without compromising quality, supporting critical project timelines.

8. Sustainable Practices: Eco-friendly manufacturing aligns with ISO 14001 standards, minimizing environmental impact.

9. Cost Efficiency: Durable fittings reduce maintenance and downtime, lowering long-term operational costs for refining and metallurgical plants.

Consult with WALKSON Today

Enhance your high-pressure systems with WALKSON’s high alloy and nickel-based centrifugal cast pipe fittings. Engineered for reliability, corrosion resistance, and compliance with stringent industry standards, our fittings deliver outstanding performance in petrochemical, oil refining, and metallurgical applications.

Contact WALKSON now to explore your project requirements, request a quote, or arrange a consultation with our technical specialists. Visit www.walkson.com or email info@walkson.com (mailto:info@walkson.com). Partner with WALKSON, a high-tech enterprise recognized by Jiangsu Province, for high-quality centrifugal casting solutions trusted by global industry leaders.

English

English  Deutsch

Deutsch  français

français  русский

русский  فارسی

فارسی  العربية

العربية  Español

Español  日本語

日本語  한국어

한국어  italiano

italiano  português

português  dansk

dansk  Suomi

Suomi